8 307-706

INSTALLATION

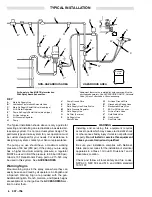

Connect the Fluid Line

(See Typical Installation)

1.

Before connecting the fluid line (N), blow it out

with air and flush it with solvent. Use solvent which is

compatible with the fluid to be sprayed.

2.

Install a fluid regulator (M) on the fluid line to con-

trol fluid pressure to the gun.

3.

Install a fluid filter (K) and drain valve (V) at the

pump outlet.

4.

Connect fluid line to 1/4–18.6(m) gun fluid

inlet (X).

WARNING

The

fluid drain valve (V) is required in your system to

assist in relieving fluid pressure in the displacement

pump, hose and gun; triggering the gun to relieve

pressure may not be sufficient. The drain valve

reduces the risk of property damage or serious bod-

ily injury, including splashing in the eyes or on skin.

Install a drain valve close to the pump’s fluid oulet.

OPERATION

WARNING

For your Safety, ALWAYS follow the Pressure

Relief Procedure on page 4 when shutting off the

system, when you stop spraying, and before

checking, servicing, installing, cleaning or chaning

any part in the system.

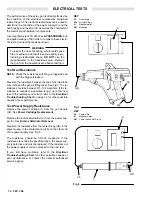

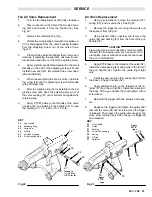

Fig 2

3 in. (76 mm)

Square Cut Out

and Finger of

Glove Cut Off

NOTE: If gloves are worn, they must

be conductive or modified as shown

so as not to interfere with operator

grounding through the gun.

Filter the Fluid

Filter the fluid to remove coarse particles and sediment

which could clog the spray nozzle.

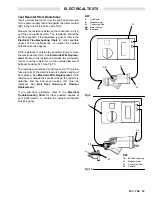

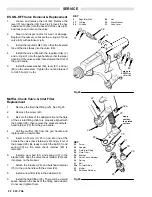

Spraying Operation

This gun has a built-in lead and lag operation. The gun

begins emitting air before the fluid is discharged. When

you release the trigger, the fluid stops before the air flow

stops. This helps prevent fluid buildup on the air cap.

When spraying, the ES indicator lights (44) should glow,

indicating the electrostatic charge. See Fig 5.

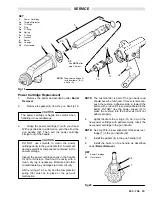

CAUTION

Be careful not to damage the electrode by jam-

ming it into an object when operating or setting

down the gun.

Operating Checklist

Check the following list daily, before starting to operate

the system, to help ensure you of safe, efficient

operation.

1.

Be sure all operators are properly trained to

safely operate an air-assisted airless electro-

static spray system.

2.

Be sure all operators are trained how to prop-

erly and completely relieve system pressure.

3.

Be sure the system is thoroughly grounded.

See FIRE, EXPLOSION, or ELECTRIC

SHOCK HAZARD, page 5, and Check the

Electrical Grounding, page 7.

4.

Be sure the operator and all persons entering

the spray area are properly grounded by wear-

ing shoes with conductive soles or personal

grounding straps.

5.

Operator must not wear gloves which insulate

the hand from the spray gun. If worn, gloves

must be conductive or modified as shown in

Fig 2 so as not to interfere with operator

grounding through the gun.

6.

Be sure ventilation fans are operating

properly.

7.

Be sure the workpiece hangers are clean and

grounded. Contact points must be sharp

points or knife edges.

8.

Be sure all refuse is removed from the spray

booth.

9.

Be sure all flammable liquids in spray booth

are in approved, grounded containers.

10. Be sure all conductive objects within 20 ft

(6 m) of the gun are electrically grounded and

the floor of the spray area is electrically con-

ductive and grounded.

Summary of Contents for PRO AA4000

Page 2: ... ...