Repair

309297K

39

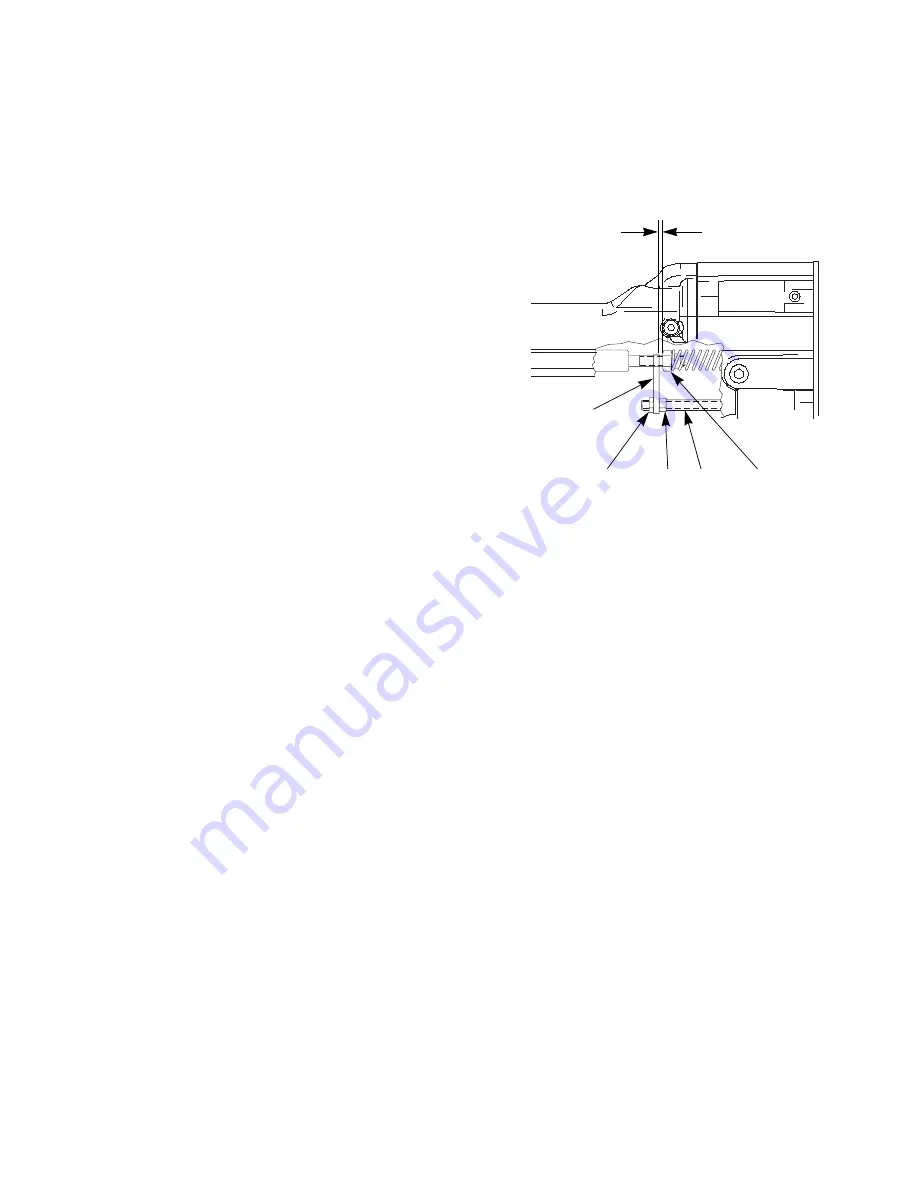

Adjust the Actuator Arm

The fluid nozzle (4) must be in place when removing or

installing the jam nut and actuator arm.

1.

Install the adjustment nut (30), actuator arm (29),

and jam nut (28) onto the piston rod (34b). Note that

the jam nut (28) has a slightly larger hex and a thin-

ner profile than the adjustment nut (30). See F

2.

Position the parts so there is a 0.125 in. (3 mm) gap

between the actuator arm (29) and the fluid packing

rod nut (E), which allows the atomizing air to actuate

before the fluid. See F

27.

3.

Tighten the adjustment nut (30) against the actuator

arm (29). Check that the 0.125 in. (3 mm) gap has

been maintained. In addition, there should be 3-4

mm of electrode needle travel when the gun is trig-

gered. Adjust the jam nut position to obtain these

dimensions.

4.

Test gun resistance, page 26.

5.

Install the gun shroud (2) and air cap (3), page 34.

6.

Install the gun onto the manifold and bracket. See

page 33.

Fig. 27. Actuator Arm Adjustment

TI1567A

28

29

30

34b

E

0.125 in. (3 mm) gap

Summary of Contents for PRO Auto Xs Series

Page 44: ...Repair 44 309297K Notes ...