Operation

18

309297K

Operating Checklist

Check the following list daily, before starting to operate

the system, to help ensure you of safe, efficient opera-

tion.

Select a Fluid Nozzle and Air

Cap

The gun is supplied with Part No. 197266 Nozzle and

24A438 Air Cap. If you require a different size, refer to

Table 2 and Table 3 , and instruction manual 309419, or

consult with your Graco distributor. See Air Cap/Nozzle

Replacement on page 34.

* Also available in the following colors: 24A276 - blue,

24A277 - red, 24A278 - green

All operators are properly trained to safely

operate an automatic electrostatic air spray

system as instructed in this manual.

All operators are trained in the Pressure

Relief Procedure on page 17.

The warning sign provided with the gun is

mounted in the spray area where it can be

easily seen and read by all operators.

The system is thoroughly grounded and the

operator and all persons entering the spray

area are properly grounded. See Grounding

on page 13.

The condition of the gun’s electrical compo-

nents has been checked as instructed in Elec-

trical Tests on page 26.

Ventilation fans are operating properly.

Workpiece hangers are clean and grounded.

All debris, including flammable fluids and rags,

is removed from the spray area.

All flammable fluids in the spray booth are in

approved, grounded containers.

All conductive objects in the spray area are

electrically grounded and the floor of the spray

area is electrically conductive and grounded.

The manifold exhaust tubes have been

checked for the presence of any fluid as

instructed in Check for Fluid Leakage on

page 25.

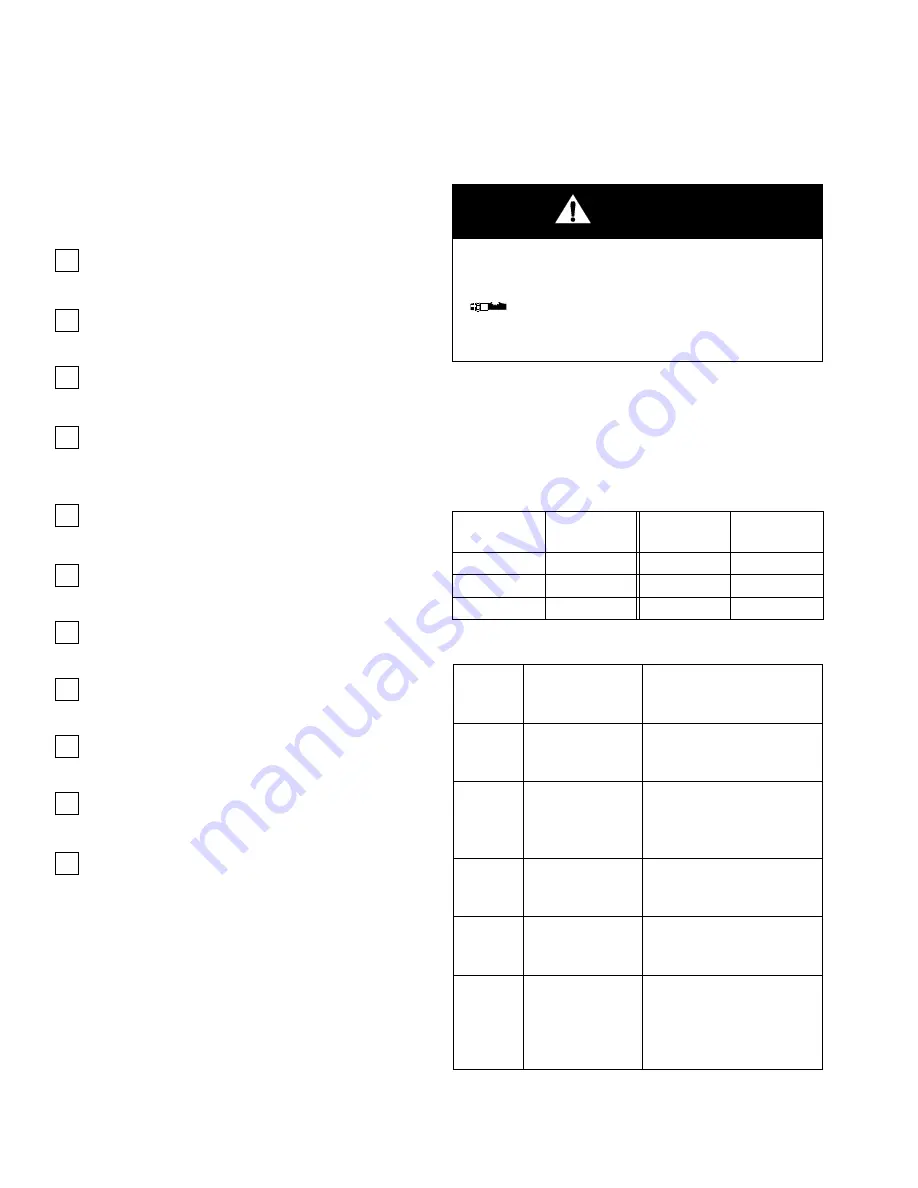

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 17

before removing or installing a fluid nozzle

and/or air cap.

Table 2: Fluid Nozzles

Part No.

Size,

mm (in.)

Part No.

Size,

mm (in.)

197263

0.75 (.030)

197266

1.5 (.055)

197264

1.0 (.042)

197267

1.8 (.070)

197265

1.2 (.047)

197268

2.0 (.080)

Table 3: Air Caps

Part No.

Pattern Shape

and Length in.

(mm)

Recommended Fluids and

Production Rates

24A438

Round end;

15-17 (381-432)

Light to medium viscosity.

Up to 15 oz/min (450

cc/min)

24A279

Round end;

14-16 (356-406)

Medium to high viscosity

and high solids.

Up to 15 oz/min (450

cc/min)

24A376*

Tapered end;

17-19 (432-483)

Light to medium viscosity.

Up to 15 oz/min (450

cc/min)

24A274

Tapered end;

12-14 (305-356)

Light to medium viscosity.

Up to 15 oz/min (450

cc/min)

24A439

Round end;

11-13 (279-330)

Medium to high viscosity

and high solids.

Up to 15 oz/min (450

cc/min)

For use with 2.0 mm nozzle.

Summary of Contents for PRO Auto Xs Series

Page 44: ...Repair 44 309297K Notes ...