Operation

309457G

23

Adjust the Spray Pattern

Follow the steps below to establish the correct fluid flow

and air flow. Do not turn on the turbine air (TA) yet.

1.

Discharge the system voltage (page 21).

2.

Relieve the pressure (page 21).

3.

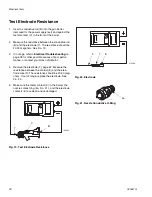

Loosen the air cap retaining ring, and rotate the air

cap for a vertical or horizontal spray pattern. See

F

. 13.. Tighten the retaining ring until the air cap is

held firmly in place; you should not be able to rotate

the air cap horns by hand.

Fig. 13. Air Cap Positions

4.

Adjust the fluid flow with the fluid pressure regulator.

Refer to instruction manual 309419 to set the fluid

pressure for various fluid flows, according to the size

of the fluid nozzle being used.

WARNING

Fire and Explosion Hazard

To reduce the risk of fire and explosion, only

use this equipment with fluids that meet at

least one of the following conditions for

non-flammability:.

•

The fluid has a flash point above 140

°

F (60

°

C)

and a maximum organic solvent concentration of

20%, by weight, per ASTM Standard D93.

•

The fluid does not sustain burning when tested

per ASTM Standard D4206 Sustained Burn Test.

WARNING

Electric Shock Hazard

Contact with the charged components of

the spray gun will cause an electric shock.

Do not touch the gun nozzle or electrode or

come within 2 ft (0.61 m) of the front of the

gun during operation or until performing the Fluid

Voltage Discharge and Grounding Procedure on

page 21.

Follow the Fluid Voltage Discharge and Grounding

Procedure on page 21 when you stop spraying and

whenever you are instructed to discharge the voltage.

WARNING

Component Rupture Hazard

To reduce the risk of component rupture,

which can cause serious injury, do not

exceed the maximum working pressure of

the lowest rated system component. This equipment

has a 100 psi (0.7 MPa, 7 bar) maximum working air

and fluid pressure.

WARNING

Pressurized Equipment Hazard

To reduce the risk of an injury, follow the

Pressure Relief Procedure on page 21

whenever you are instructed to relieve the

pressure.

Vertical Pat-

Horizontal Pat-

Summary of Contents for PRO Auto Xs

Page 51: ...Repair 309457G 51 ...