Repair

309457G

41

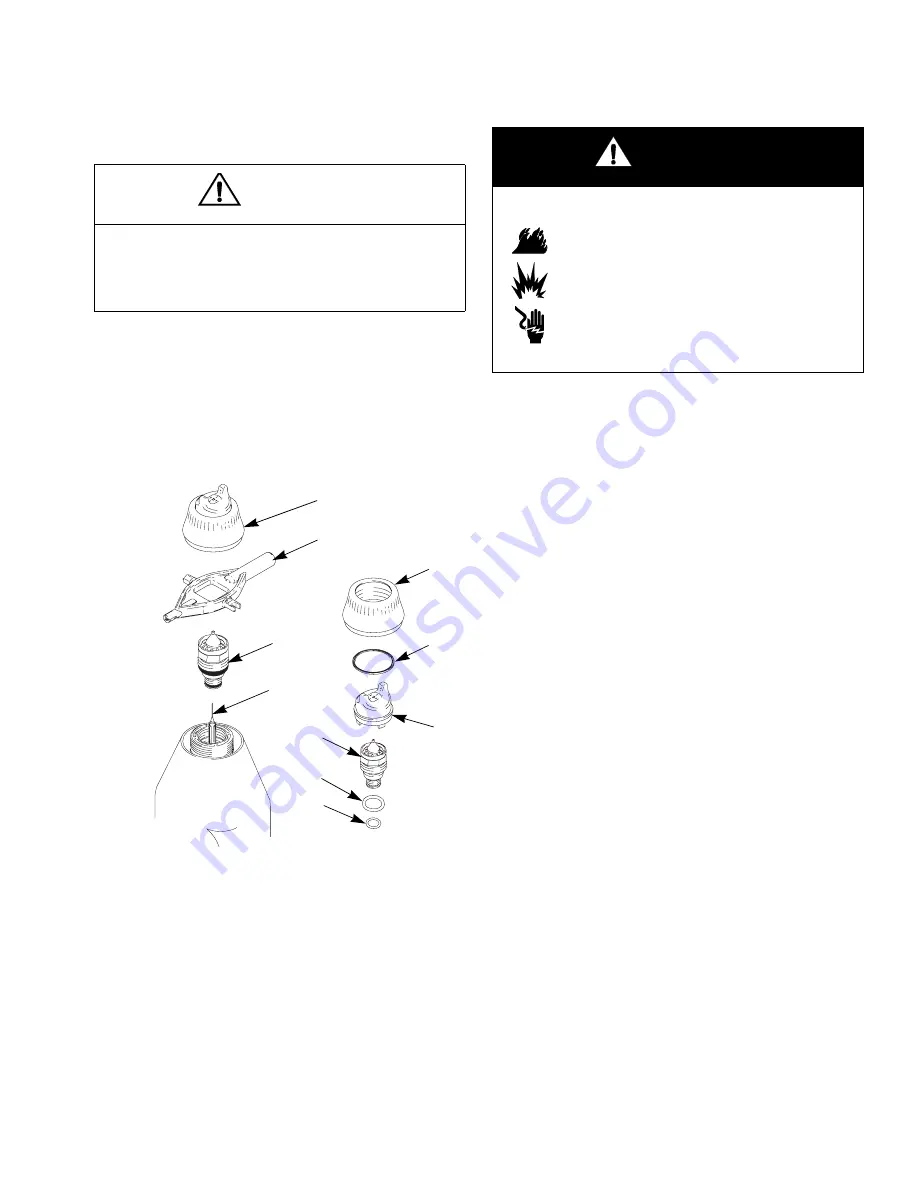

Air Cap/Nozzle Replacement

1.

Prepare gun for service, page 39.

2.

Remove the retaining ring (1) and air cap (3). See

F

3.

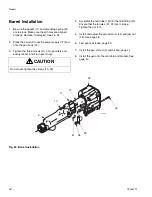

Point gun up while removing the fluid nozzle (4)

assembly with the multi-tool (40).

Fig. 23. Air Cap/Nozzle Replacement

NOTE: Use non-silicone grease, Part No. 111265, on

the small o-ring (4b). Do not over-lubricate. Do not lubri-

cate the contact ring (4a).

4.

Lightly lubricate the o-ring (4b). Install it and the

contact ring (4a) on the nozzle (4).

NOTE: Make sure the electrode needle (7) is finger-

tight (page 42).

5.

Install the fluid nozzle (4) with the multi-tool (40).

Tighten until the fluid nozzle seats in the gun barrel

(1/8 to 1/4 turn past hand-tight).

6.

Carefully install the air cap (3). Be sure to insert the

electrode (7) through the center hole of the air cap.

Rotate the air cap to the desired position.

7.

Make sure the u-cup (1a) is in place on the retaining

ring (1). The lips must face forward. Tighten the

retaining ring until the air cap is held firmly in place;

you should not be able to rotate the air cap horns by

hand.

8.

Test gun resistance, page 30.

9.

Install the gun onto the manifold and bracket. See

page 40.

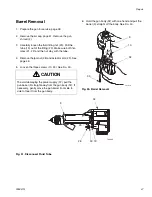

CAUTION

Hold the front end of the gun up and trigger the gun

while removing the nozzle to help drain the gun and

prevent any paint or solvent left in the gun from enter-

ing the air passages.

TI1572A

1, 3

3

4

4a

4b

1

40

4

7

1a

WARNING

Fire, Explosion, and Electric Shock Hazard

The nozzle contact ring (4a) is a conductive

contact ring, not a sealing o-ring. To reduce

the risk of sparking or electric shock, do not

remove the nozzle contact ring (4a) except

to replace it and never operate the gun with-

out the contact ring in place. Do not replace

the contact ring with anything but a genuine

Graco part.

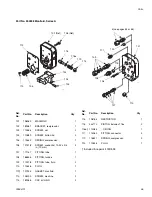

Summary of Contents for PRO Auto Xs

Page 51: ...Repair 309457G 51 ...