Soft

Soft

Soft Spray

Spray

Spray Gun

Gun

Gun Setup

Setup

Setup Procedure

Procedure

Procedure

To convert a gun to achieve a soft spray pattern for

small or lightweight parts, do the following:

1.

Install a soft spray air cap. See

Air Cap Selection Guide, page 80

2.

For best results, install a 1.0 mm

or 1.2 mm fluid nozzle.

See

Fluid Nozzle Selection Chart, page 77

.

3.

Follow steps 1–13 in the

4.

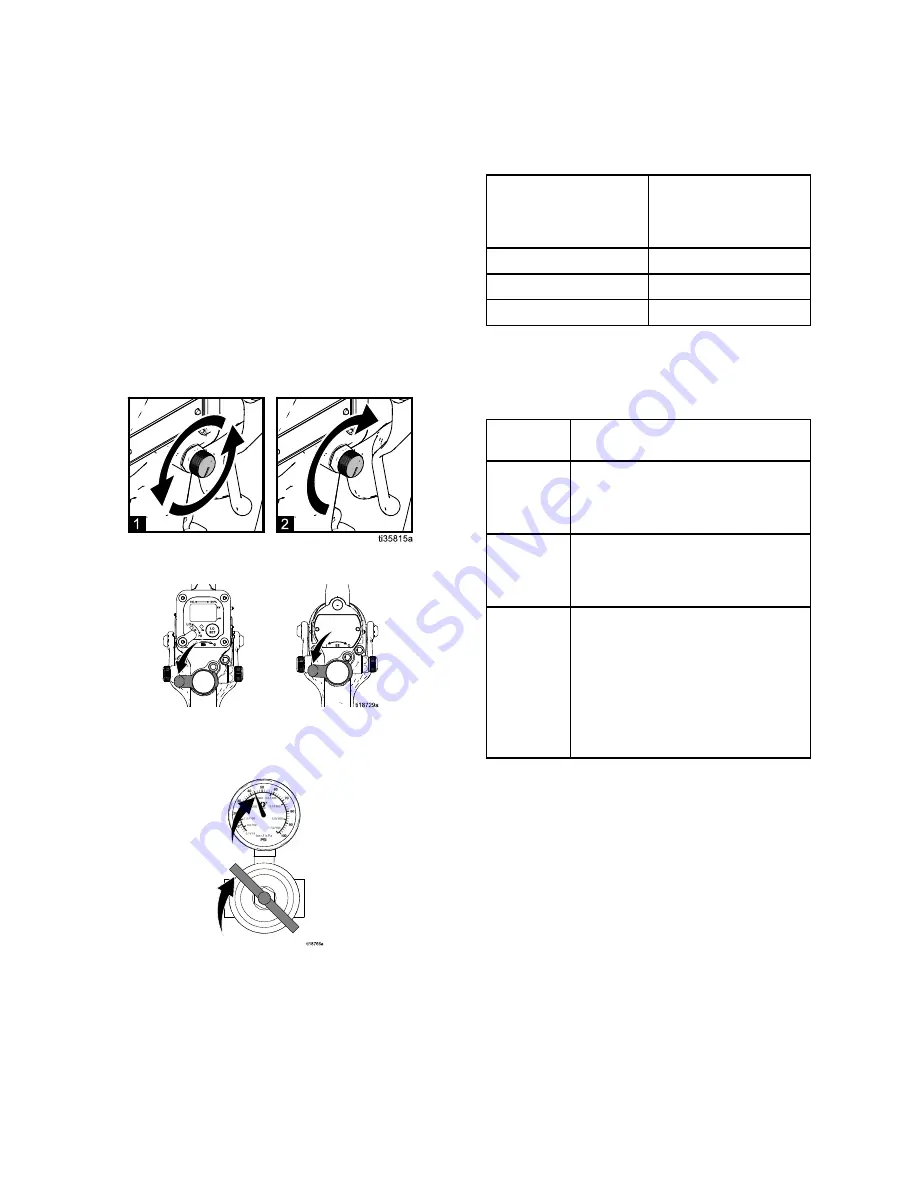

Adjust the atomizing air. Fully close the atomizing

air restrictor valve (G) counterclockwise. Then,

open the atomizing air restrictor valve (G) one

half turn to one turn.

5.

Turn ON (I) the ES On-Off switch (J).

6.

Set the gun air regulator to deliver a minimum

45 psi (0.32 MPa, 3.2 bar) at the gun when

triggered, to ensure full spraying voltage.

Table

Table

Table 4

4

4 Pressure

Pressure

Pressure Drop

Drop

Drop

Air

Air

Air Hose

Hose

Hose

Length

Length

Length in

in

in ft

ft

ft (m)

(m)

(m)

using

using

using 5/16

5/16

5/16 inch

inch

inch (8

(8

(8

mm)

mm)

mm) diameter

diameter

diameter hose

hose

hose

Air

Air

Air Regulator

Regulator

Regulator Setting

Setting

Setting

in

in

in psi

psi

psi (MPa,

(MPa,

(MPa, bar)

bar)

bar)

with

with

with gun

gun

gun triggered

triggered

triggered

15 (4.6)

55 (0.38, 3.8)

25 (7.6)

65 (0.45, 4.5)

50 (15.3)

80 (0.56, 5.6)

7.

Verify that the ES indicator (K) [Hz indicator on

Smart guns] is lit.

Table

Table

Table 5

5

5 LED

LED

LED Indicator

Indicator

Indicator Colors

Colors

Colors

Indicator

Indicator

Indicator

Color

Color

Color

Description

Description

Description

Green

When spraying, the indicator

should remain green, indicating

sufficient air pressure to the

alternator turbine.

Amber

If the indicator changes to amber

after one second, the air pressure

is too low. Increase air pressure

until the indicator is green.

Red

If the indicator changes to red

after one second, the air pressure

is too high. Decrease air pressure

until the indicator is green. To

maintain a higher application air

pressure, install ES On/Off Valve

Restrictor Kit 26A160. Adjust the

pressure as needed to ensure the

indicator remains green.

8.

Continue with steps 18–23 in the

Note

The soft spray air cap is optimized for

a production rate of 3.5 oz/min (100

cc/min). For best soft spray results, limit

the production rate to 7 oz/min (200

cc/min) or less.

Note

If the object being sprayed is moving too

much, adjust the atomizing air restrictor

valve (G) counterclockwise slightly to

limit the air flow. To improve atomization,

adjust the atomizing air restrictor valve

(G) clockwise slightly to increase the air

flow or decrease the fluid flow.

24

3A7504A