Series Progressive Lubrication Systems Installation Guide

L40000

Page 5

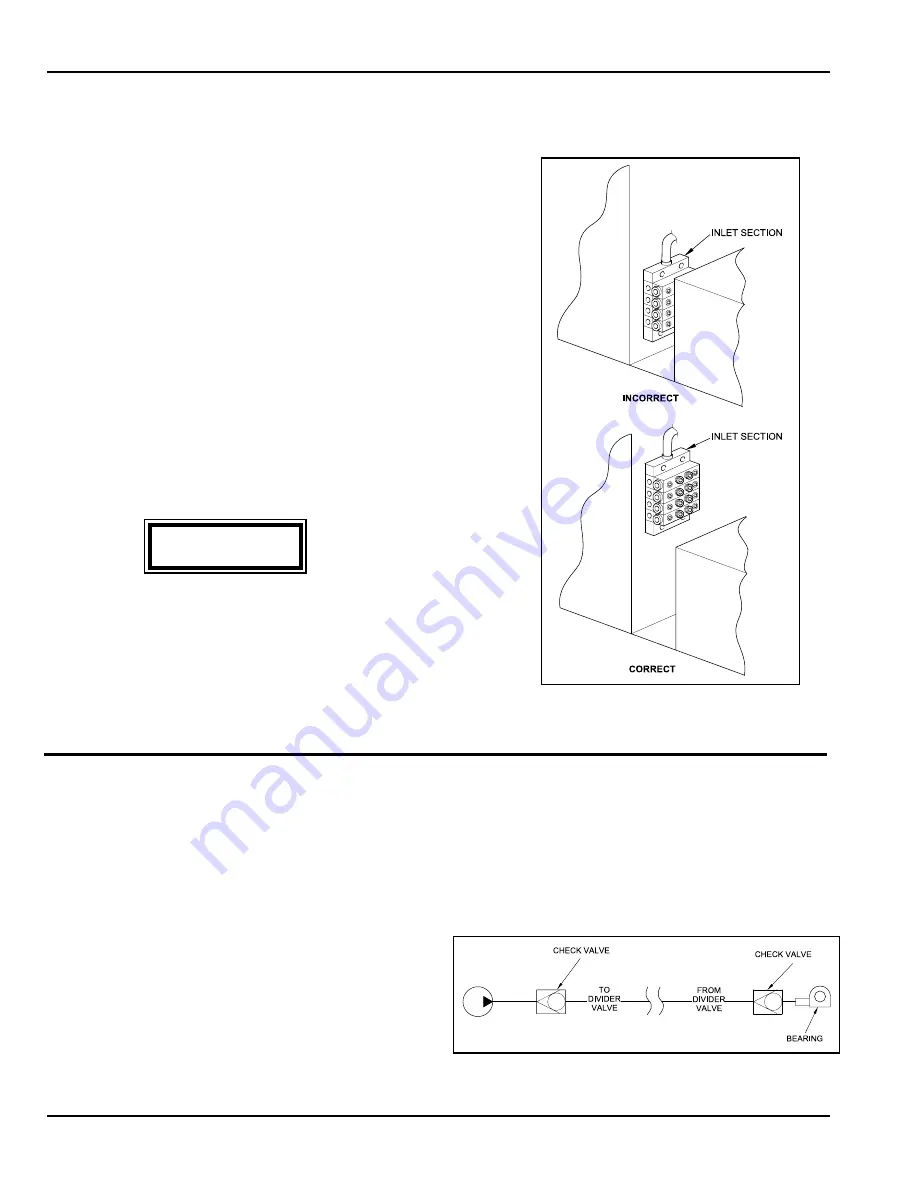

MOUNTING DIVIDER VALVES

(continued)

Avoid locating the divider valve assembly in locations that

•

restrict access to it. The ports on the front of the divider

valves should be acces sible for prefilling and purging

procedures (see Figure 5).

The inlet and end sections of each divider valve have two

holes each to enable the installer to attach it to an appropriate

surface with properly-sized bolts. The valves may be attached

directly to one of the machine surfaces if the surface can be

drilled and tapped, but the mounting surface should be flat in

order to prevent the divider valve from being deformed. Other

mounting variations may require the use of a mounting plate

interface. Graco has several styles of mounting plates available

for straightforward installations. Also, a customized design

can be developed for those installations that require special

considerations and hardware.

CAUTION

If a weld-in-place mounting plate is be ing installed, the plate

should be welded in place prior to mounting the divider valve

assembly in order to pre vent damage to the internal 0-rings by

heat generated during the welding op eration.

Figure 5

be placed as close as possible to the final lubrication point (see

Figure 6). This prevents drainage of lubricant from the lube

lines should disassembly be required. However, systems using

grease as the lubricant may not experience lubricant self-flow

when com ponents are removed and, therefore, may not require

lube point check valves.

INSTALLING CHECK VALVES

After the divider valves have been located, the check valves

should be installed with each one oriented so that it faces

toward the particular divid er valve outlet port that supplies it

with lubricant. This helps to determine the minimum length of

connecting tubing or hose.

There are several locations within any lubrication system that

benefit from the use of a check valve, including the outlet of

the pump and the ends of all lube lines. The check valve should

Figure 6