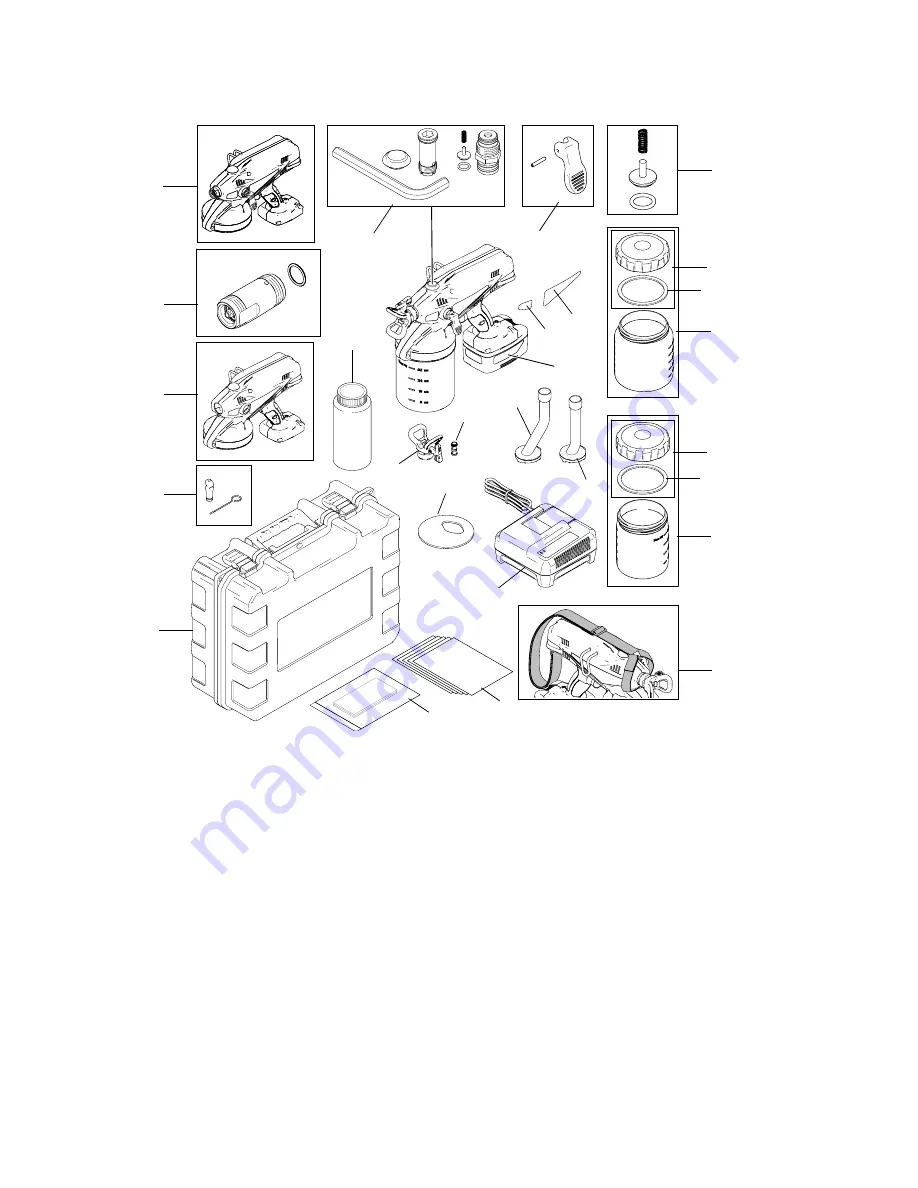

Replacement Parts and Kits

16

3A0153E

Replacement Parts and Kits

1

8

11

6

5

4

3

7

12

16

ti15497a

2

15

14

17

9

10

18

20

19

21

22

23

24

ti16473c

13a

13

13a

13

Ref. Part

Description

1

262367

Sprayer, replacement (no tip, battery, suction

tube, or material cup)

2

16D562

Liner, replacement (10 pack)

3

24F045

Fine Finish Optimizer (with Cleaning Tool)

2-Pack

4

243103

Pump Armor (32 oz.)

5

24F042

Storage Case

6

16D563

Repair Kit

(includes inlet/outlet valve wrench)

7

ProShot Tip/Guard Assembly

PST211

211

PST213

213

PST315

315

PST411

411 (included with sprayer)

PST413

413

PST515

515 (factory-installed on sprayer)

PST517

517

8

Tip Filter

24E376

Kit, 1-pack

24F039

Kit, 3-pack

9

24F044

Specialized Suction Tube with screens and

o-rings (for spraying floors)

10

24F043

Standard Suction Tube with screens and o-rings

(for walls and ceilings)

11

16D558

Lithium Ion Premium Power Battery

12

16E403

Sprayer Cup Seal

13

24D425

Cover with seal (included in 16 and 17)

13a

16C650

Material Cup Cover Seal (included in 16 and 17)

14

16D559

Lithium Ion Battery Charger (120 VAC)

16G615

Lithium Ion Battery Charger (240 VAC)

15

▲

24E609 Warning Labels Kit (ENG/FRA/SPA)

▲

24H616 Warning Labels Kit (SPA/POR/ITA)

16

16D560

Material Cup (32 oz) cover and seal

17

16D561

Material Cup (48 oz) cover and seal

18

24E377

Shoulder Strap

106553

Suction Tube o-ring (not shown)

19

262602

Inlet Valve Kit

20

262437

Needle Assembly Kit

21

262601

Prime Valve Handle

22

262677

Enclosure, replacement, kit (Includes

enclosure with hook, screws, cup gasket, status

indicator lens, air filter, Made-In-USA label, and

access plug) product labels NOT included

23

16E119

Label, brand, ProShot

24

16E964

Label, brand, Hand Held

▲

Replacement Danger and Warning labels, tags, and cards are

available at no cost.

Ref. Part

Description