11

307-711

STARTUP

CAUTION

The wallet sized warning card provided with the gun

should be kept with the operator at all times. The

card contains important information on reducing the

risk of a fluid injection injury, and treatment informa-

tion should an injection injury occur. Additional co-

pies of this card are available at no cost.

Pressure Relief Procedure

To reduce the risk of serious bodily injury, including

fluid injection, splashing in the eyes or on the skin,

injury from moving parts, or electric shock, always

follow this procedure whenever you shut off the

sprayer, when checking or servicing any part of the

spray system, when installing, cleaning or changing

spray tips, and whenever you stop spraying.

1.

Shut off the sprayer and unplug it.

2.

Hold a metal part of the gun firmly to the side of

a grounded metal pail, and trigger the gun into

the pail to relieve pressure.

3.

Engage the trigger safety lever.

4.

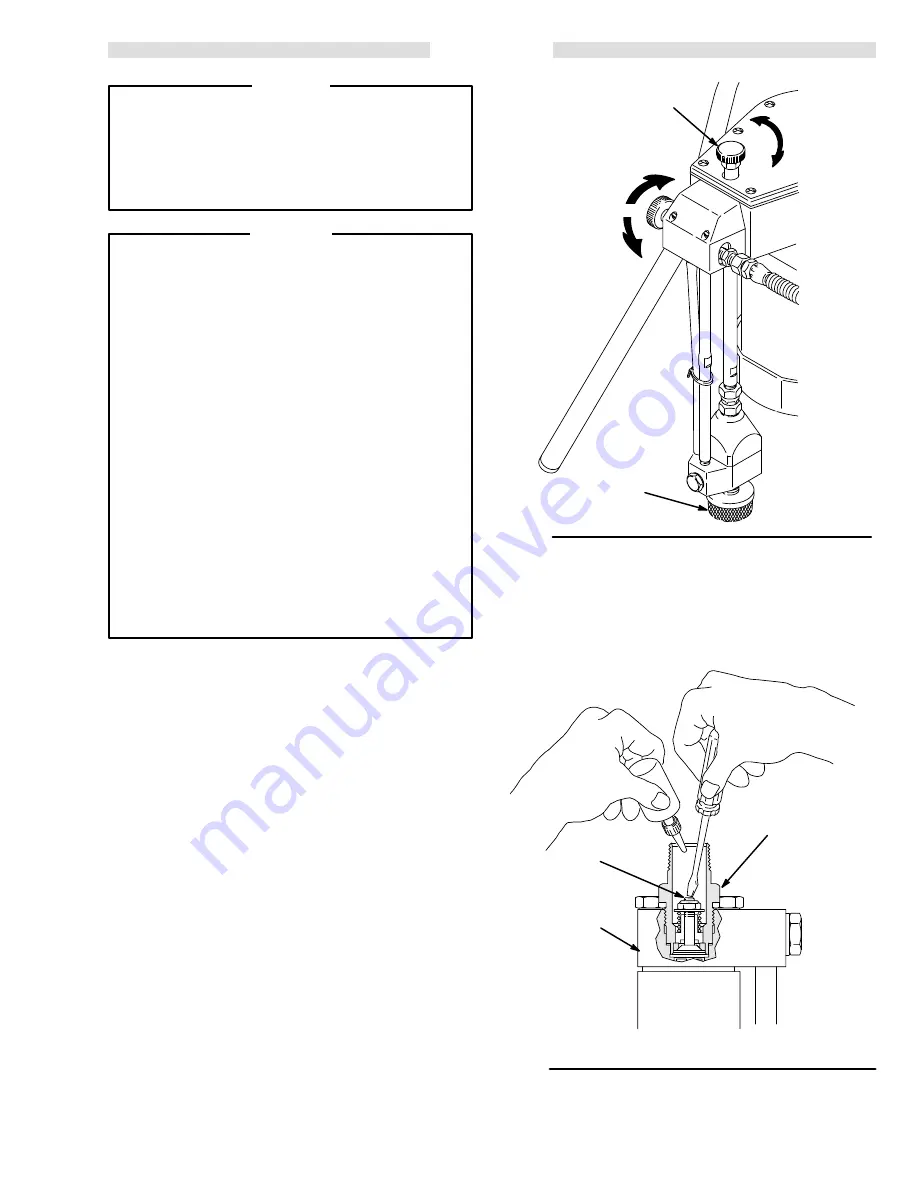

Turn the bypass valve counterclockwise one

turn to drain paint back into the pail.

If you suspect that the spray tip or hose is complete-

ly clogged, or that pressure has not been fully re-

lieved after following the steps above, very slowly

loosen the tip guard retaining nut or hose end cou-

pling and relieve pressure gradually, then loosen

completely. Now clear the tip or hose obstruction.

WARNING

1.

Open the bypass valve ONE turn counterclock-

wise. Do not place the pump intake in the pail yet.

See Fig 3.

2.

Turn the pressure control fully clockwise to increase

pressure. See Fig 3.

3.

Remove the inlet strainer and place your hand over

the inlet valve to be sure it is drawing a vacuum.

NOTE: If the inlet valve is not drawing a vacuum, turn the

sprayer OFF. Turn the sprayer over. Press down

on the stem inside the inlet valve lightly with a

small screwdriver, and pour about a teaspoon of

mineral spirits or solvent into the valve. See Fig

4. Release the valve and turn the sprayer up-

right. With the pressure turned up, turn on the

sprayer. This should free any sticking parts in the

pump. Now check again for a vacuum. Shut off

the sprayer and install the inlet strainer.

4.

Place the paint pump assembly into a properly pre-

pared 5 gallon pail of paint. (See Step 1, page 10.)

5.

Turn the sprayer ON and allow the paint to circulate

through the bypass valve for one or two minutes.

NOTE: If the paint does not circulate back into the pail,

turn down the pressure and “jog” the motor on

and off several times to help prime the sprayer.

6.

Turn the bypass valve clockwise (finger tight) to

close it; this allows the pump to build up pressure.

PRESSURE CONTROL

Fig 3

Fig 4

PAINT PUMP

INLET VALVE

PUMP SHOWN UPSIDE DOWN

INLET STRAINER

CLOSE

Clockwise

OPEN

Counterclockwise

INCREASE

Clockwise

0271

0272

STEM

BYPASS VALVE

STARTUP PROCEDURE CONTINUED ON PAGE 12