16

307-711

TROUBLESHOOTING

To reduce the risk of serious bodily injury, including

fluid injection, always follow the Pressure Relief

Procedure Warning on page 11 before checking or

repairing any part of the spray system.

WARNING

NOTES:

1.

Repairs, other than those for which instructions are

given on page 18, should be performed by a trained

and qualified repair agency.

2.

If your sprayer is not operating well, or will not oper-

ate at all, check for obvious problems first. Follow the

STARTUP procedure exactly (see page 11). Then if

the sprayer won’t start, use the Troubleshooting

Chart for help in identifying the possible cause.

3.

Remember, taking the time after each use of the

sprayer to perform all of the maintenance proce-

dures given on page 13 and 14 will help prevent down

time and costly repair bills.

TROUBLESHOOTING CHART

PROBLEM

CAUSE

SOLUTION

Poor spray pattern

Spray tip worn

Change tip

Paint too thick

Thin, try larger tip

Spray gun won’t shut off

Worn ball

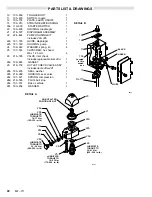

Repair gun; order kit no. 218–588

Worn diffuser

Replace gun

Paint build-up between needle and

diffuser

Disassemble and clean gun

Spray gun leaks

Worn seal or loose fluid fitting

Repair gun; order Kit no. 218–588;

tighten fluid fitting.

Spray gun won’t spray, or low

output from gun

Paint supply empty

Refill and reprime system.

Spray tip clogged

Use Reverse-A-Clean feature to

clear tip clog; see page 12

Gun filter, if used, is clogged

Clean or replace

Sprayer will not start

Sprayer not plugged in

Plug in

ON/OFF switch turned off

Turn switch on

Sprayer left pressurized when shut

off

Relieve pressure first, then start

Motor overheated

Shut off, relieve pressure, allow to

cool

NOTE: Sprayer restarts automati-

cally when cool if it is left on

Blown building fuse or circuit

breaker tripped

Replace or reset

No voltage or low voltage in

electrical outlet

Test the outlet or try plugging spray-

er into another outlet

Damaged power supply cord or

extension cord, or wrong type of

extension cord

Return for repair; use only 3 wire, 16

gauge (minimum) extension cord

with a 3 prong plug and a maximum

length of 30 m (100 ft.)

Starter switch (18a) damaged

Replace; see page 18

Motor worn or damaged

Return for repair

Motor runs but sprayer won’t run

Air in diaphgram housing

Bleed air