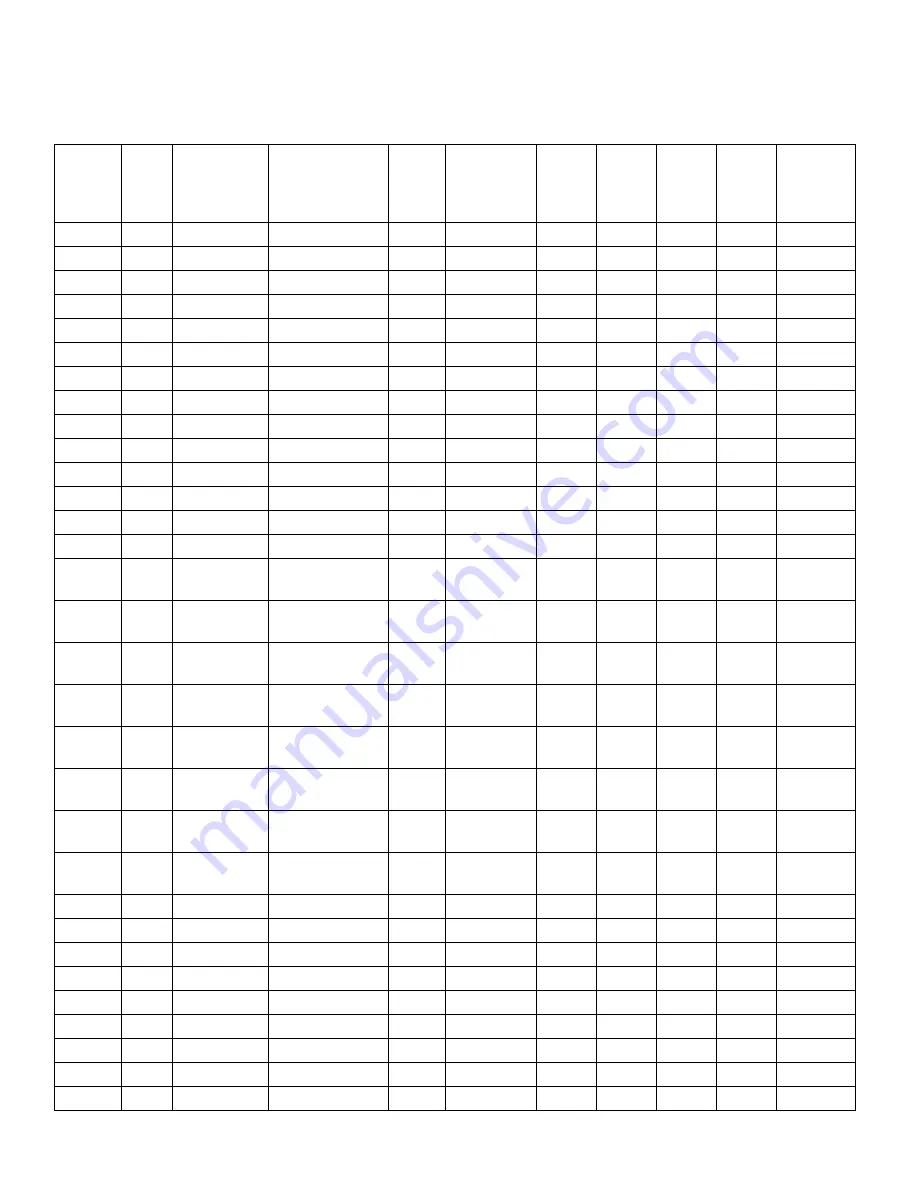

Models

2

312101E

Models

Part

Number Series Spray Type

Max HVLP/

Comp Pressure

psi (MPa, bar)

Nozzle

(mm)

Application

Air

Cap

Nozzle

Needle

Assy

Needle

Tip

Air Cap

with

Retaining

Ring

288561

A

LVLP

16 (0.1, 1.1)

1.2

Clear, Base 253823 253802 253771 288752

289500

288562

A

LVLP

16 (0.1, 1.1)

1.3

Clear, Base 253823 253803 253771 288752

289500

288563

A

LVLP

16 (0.1, 1.1)

1.4

Clear, Base 253823 253804 253772 253917

289500

288564

A

LVLP

16 (0.1, 1.1)

1.5

Clear, Base 253823 253805 253772 253917

289500

288565

A

LVLP

16 (0.1, 1.1)

1.6

Clear, Base 253823 253806 253772 253917

289500

288566

A

HVLP

29 (0.2, 2.0)

1.0

Clear, Base 253824 253792 253769 288751

289501

288567

A

HVLP

29 (0.2, 2.0)

1.2

Clear, Base 253824 253793 253771 288752

289501

288568

A

HVLP

29 (0.2, 2.0)

1.3

Clear, Base 253824 253794 253771 288752

289501

288569

A

HVLP

29 (0.2, 2.0)

1.4

Clear, Base 253824 253795 253772 253917

289501

288570

A

HVLP

29 (0.2, 2.0)

1.5

Clear, Base 253824 253796 253772 253917

289501

288571

A

HVLP

29 (0.2, 2.0)

1.7

Clear, Base 253824 253797 253772 253917

289501

288572

A

HVLP

29 (0.2, 2.0)

1.5

Primer

253828 253789 253772 253917

289505

288573

A

HVLP

29 (0.2, 2.0)

1.8

Primer

253828 253790 253772 253917

289505

288574

A

HVLP

29 (0.2, 2.0)

2.3

Primer

253829 253791 253774 234779

289506

288575

A

Compliant

35 (0.24, 2.4)

1.0

Clear, Base,

Primer

253825 253816 253769 288751

289502

288576

A

Compliant

35 (0.24, 2.4)

1.2

Clear, Base,

Primer

253825 253817 253771 288752

289502

288577

A

Compliant

35 (0.24, 2.4)

1.3

Clear, Base,

Primer

253825 253818 253771 288752

289502

288578

A

Compliant

35 (0.24, 2.4)

1.4

Clear, Base,

Primer

253825 253819 253771 288752

289502

288657

A

Compliant

35 (0.24, 2.4)

1.5

Clear, Base,

Primer

253825 288653 253772 253917

289502

288579

A

Compliant

35 (0.24, 2.4)

1.6

Clear, Base,

Primer

253825 253820 253772 253917

289502

288580

A

Compliant

35 (0.24, 2.4)

2.0

Clear, Base,

Primer

253826 253821 253774 234779

289503

288581

A

Compliant

35 (0.24, 2.4)

2.5

Clear, Base,

Primer

253826 253822 253775 234780

289503

288582

A

Conventional

N/A

1.2

Clear, Base 288451 288295 253772 253917

289507

288583

A

Conventional

N/A

1.3

Clear, Base 288451 288296 253772 253917

289507

288584

A

Conventional

N/A

1.4

Clear, Base 288451 288297 253771 288752

289507

288585

A

Conventional

N/A

1.6

Clear, Base 288451 288298 253772 253917

289507

288586

A

Conventional

N/A

1.8

Primer

288452 288299 253772 253917

289508

288587

A

Conventional

N/A

2.5

Primer

288453 288300 253775 234780

289509

289218

A

HVLP

29 (0.2, 2.0)

1.3

Metallic

289212 253794 253771 288752

289514

289219

A

HVLP

29 (0.2, 2.0)

1.4

Metallic

289212 253795 253772 253917

289514

289220

A

HVLP

29 (0.2, 2.0)

1.5

Metallic

289212 253796 253772 253917

289514