Summary of Contents for Reactor A-20

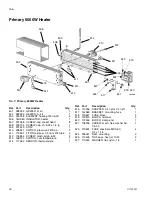

Page 31: ...Parts 311512A 31 ...

Page 35: ...Parts 311512A 35 ...

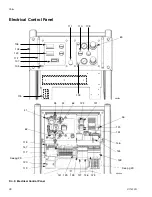

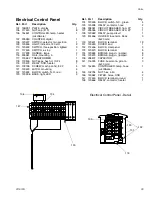

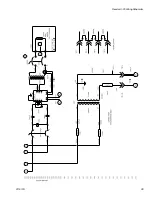

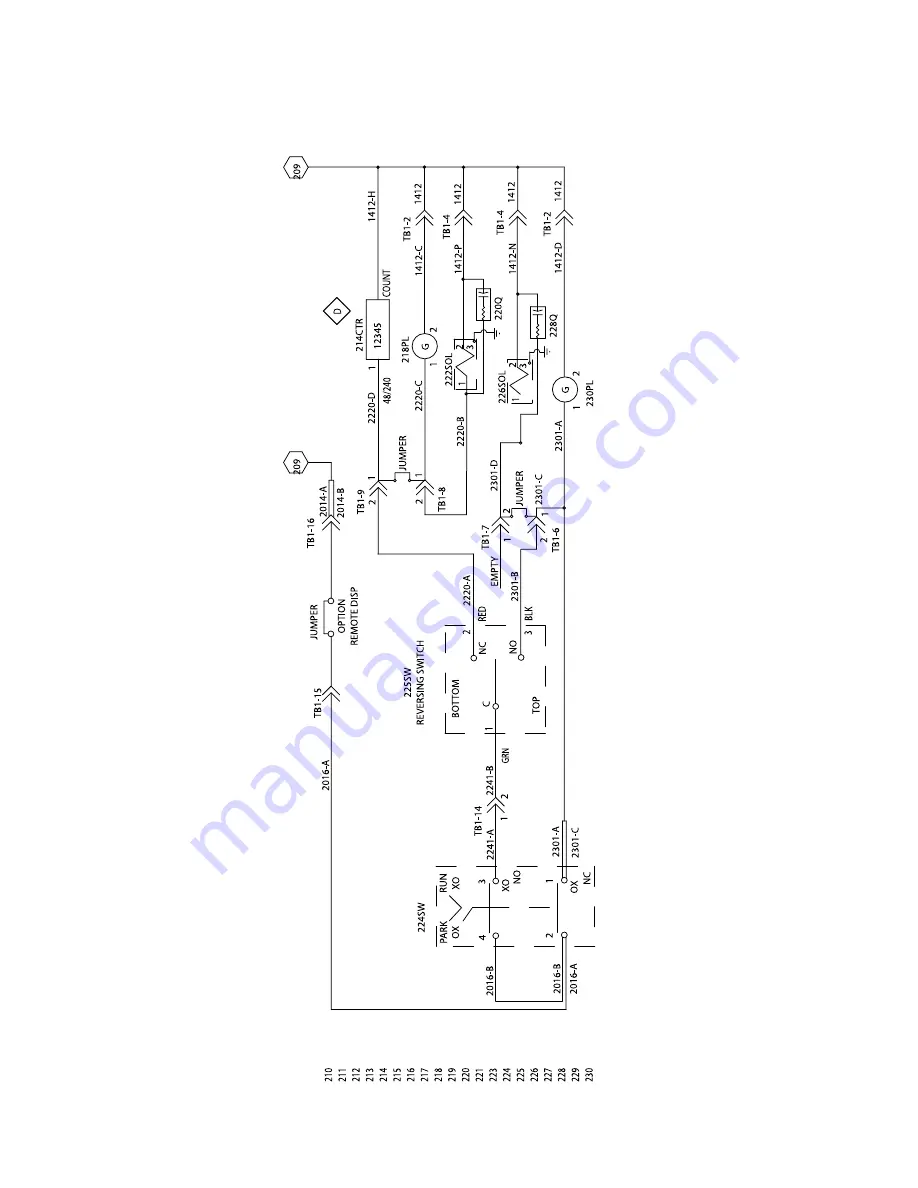

Page 38: ...Reactor A 20 Wiring Schematic 38 311512A Reactor A 20 Wiring Schematic ...

Page 39: ...Reactor A 20 Wiring Schematic 311512A 39 ...

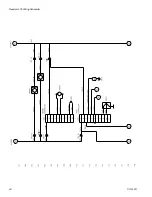

Page 40: ...Reactor A 20 Wiring Schematic 40 311512A ...

Page 41: ...Reactor A 20 Wiring Schematic 311512A 41 ...

Page 42: ...Reactor A 20 Wiring Schematic 42 311512A ...

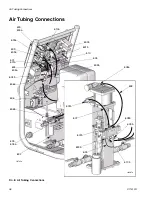

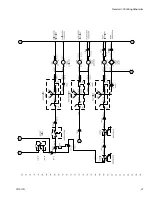

Page 43: ...Wiring Diagrams 311512A 43 Wiring Diagrams Heater Circuit ...

Page 44: ...Wiring Diagrams 44 311512A Pump Circuit ...

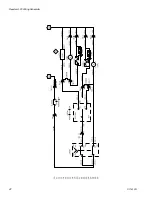

Page 45: ...Wiring Diagrams 311512A 45 Hose Circuit ...

Page 46: ...Wiring Diagrams 46 311512A ...