Troubleshooting

311512A

9

One pressure gauge drops when

pumps are stalled on the upstroke,

but not the downstroke

Piston check ball not sealing

Repair pump; see 309577

Piston packing not sealing

Repair pump; see 309577

Loose piston stud in pump

Repair pump; see 309577

Bad inside sleeve seal

Repair o-ring; see 309577

A side rich; lack of B side

A side gauge is low

B side restriction downstream of

gauge. Check gun check valve

screen, mix module, or mix manifold

restrictor.

B side gauge is low

B side material supply problem.

Check B side inlet strainer and pump

intake valve.

B side rich; lack of A side

A side gauge is low

A side material supply problem.

Check A side inlet strainer and pump

intake valve.

B side gauge is low

A side restriction downstream of

gauge. Check gun check valve

screen, mix module, or mix manifold

restrictor.

Fluid pressures not balanced

between A and B side

Fluid viscosities not equal

Sometimes normal if pressure offset

is below 200 psi (14 bar)

Preheat material in drums by recircu-

lating; see Operation manual 311511

Inlet Y-strainer screen plugged on low

pressure side

Clean inlet filter screen

Gun port or filter plugged on high

pressure side

Clean or replace; see gun manual

Pump inlet ball not seating or sticking Clean seating; see pump manual

Drum fluid outlet supply hose too

small

Use 3/4 in. (1.9 cm) ID hose with

short length

Low side feed pump not working

Turn on or repair feed pump

Pump does not reverse direction

Obstruction of air motor or pumps

Check and clear obstruction

Reversing switch failed

Check and service switch assembly;

see page 16.

Air solenoid valve failed.

Check solenoid valve, see page 16.

Unequal fluid pressure between

UP/DOWN stroke

Air regulator pressures not set cor-

rectly. Feed pumps boost pressure on

up stroke.

Adjust UP/DOWN air regulators to

create equal fluid outlet pressures;

see Operation manual 311511.

Pumps stop moving, Pump Mode

Function green knob light off

Over-pressure shutdown from imbal-

anced pressures. Plugging one side

will double the pressure. Starving

one side will double the pressure on

the other side.

Check for gun restriction, see Gun

manual

Air pressure set too high; lower air

pressure

Pump cavitating on low pressure

side; check inlet and clean strainer.

Check feed pump.

Heater plugged on low pressure side;

see Repair, page 18.

PROBLEM

CAUSE

SOLUTION

Summary of Contents for Reactor A-20

Page 31: ...Parts 311512A 31 ...

Page 35: ...Parts 311512A 35 ...

Page 38: ...Reactor A 20 Wiring Schematic 38 311512A Reactor A 20 Wiring Schematic ...

Page 39: ...Reactor A 20 Wiring Schematic 311512A 39 ...

Page 40: ...Reactor A 20 Wiring Schematic 40 311512A ...

Page 41: ...Reactor A 20 Wiring Schematic 311512A 41 ...

Page 42: ...Reactor A 20 Wiring Schematic 42 311512A ...

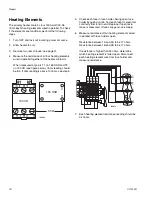

Page 43: ...Wiring Diagrams 311512A 43 Wiring Diagrams Heater Circuit ...

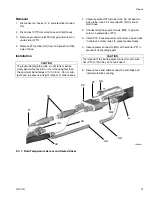

Page 44: ...Wiring Diagrams 44 311512A Pump Circuit ...

Page 45: ...Wiring Diagrams 311512A 45 Hose Circuit ...

Page 46: ...Wiring Diagrams 46 311512A ...