Troubleshooting

26

313221A

Troubleshooting

Status Codes

Determine the status code by counting the

number of times the status indicator (ST)

blinks.

Status Code 1: Pressure Imbalance

Unit senses pressure imbalance between com-

ponents A and B, and warns or shuts down,

depending on settings of DIP switches 1 and 2.

To turn off automatic shutdown and/or tighten

pressure tolerances for status code 1, see Sta-

tus Code 1 and 2 Settings on page 27.

1. Check fluid supply of lower pressure com-

ponent and refill if necessary.

2. Reduce pressure of higher component by

slightly turning Recirc/Spray valve for that

component toward Recirc, until gauges

show balanced pressures.

3. Check fluid inlet strainers (51a, page 23)

and fluid filters at gun.

4. Clean or change restrictor at mixer mani-

fold if using disposable mixer gun kit.

Status Code 2: Pressure Deviation

from Setpoint

Unit senses pressure deviation from setpoint,

and warns or shuts down, depending on set-

tings of DIP switches 3 and 4. If equipment

cannot maintain enough pressure for a good

mix with an impingement mix gun, try using a

smaller mix chamber or nozzle.

To turn off automatic shutdown and/or tighten

pressure tolerances for status code 2, see Sta-

tus Code 1 and 2 Settings on page 27.

The unit does not check for pressure

imbalance at setpoints less than 250 psi

(1.75 MPa, 17.5 bar).

The unit does not check for pressure

imbalance for 10 sec after entering pres-

sure mode.

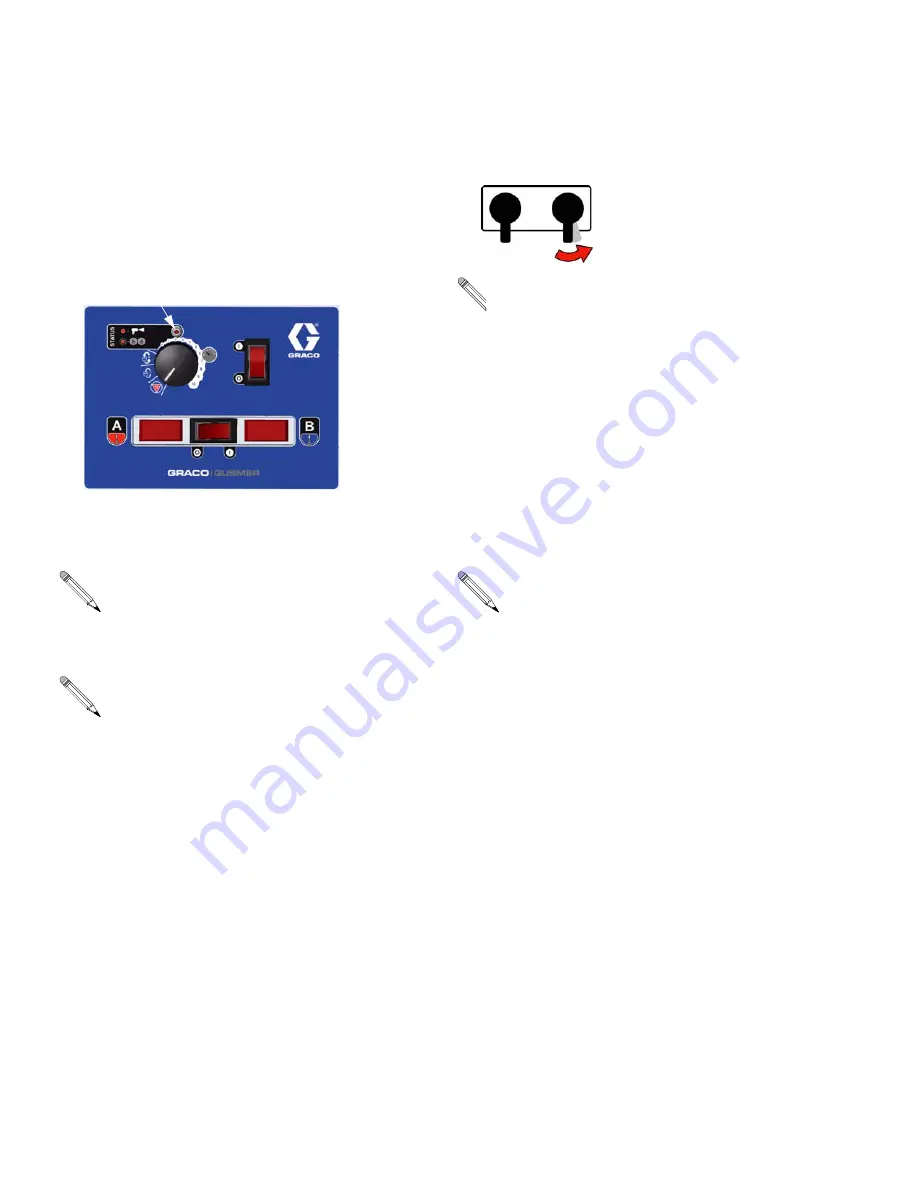

ST

TI7016a

Turn Recirc/Spray valve only enough to

balance pressure. If turned completely, all

pressure will bleed off.

The unit does not check for pressure

deviation at setpoint less than 400 psi

(2.8 MPa, 28 bar).

In this example, B side

pressure is higher, so

use the B side valve to

balance pressures.