Maintenance

332144E

25

Maintenance

•

Check pump wet-cups fluid level daily, page 18.

•

Throat u-cup is not adjustable. Do not overtighten

packing nut/wet-cup.

•

Keep component ISO from exposure to moisture in

atmosphere, to prevent crystallization.

•

Wipe supply tank lid o-ring, inner rim, and inner tank

walls daily to prevent ISO crystallization. Keep film

of grease on o-ring and inside of lid.

•

Check desiccant filter weekly. Filter is blue when

fresh, and turns pink when saturated.

•

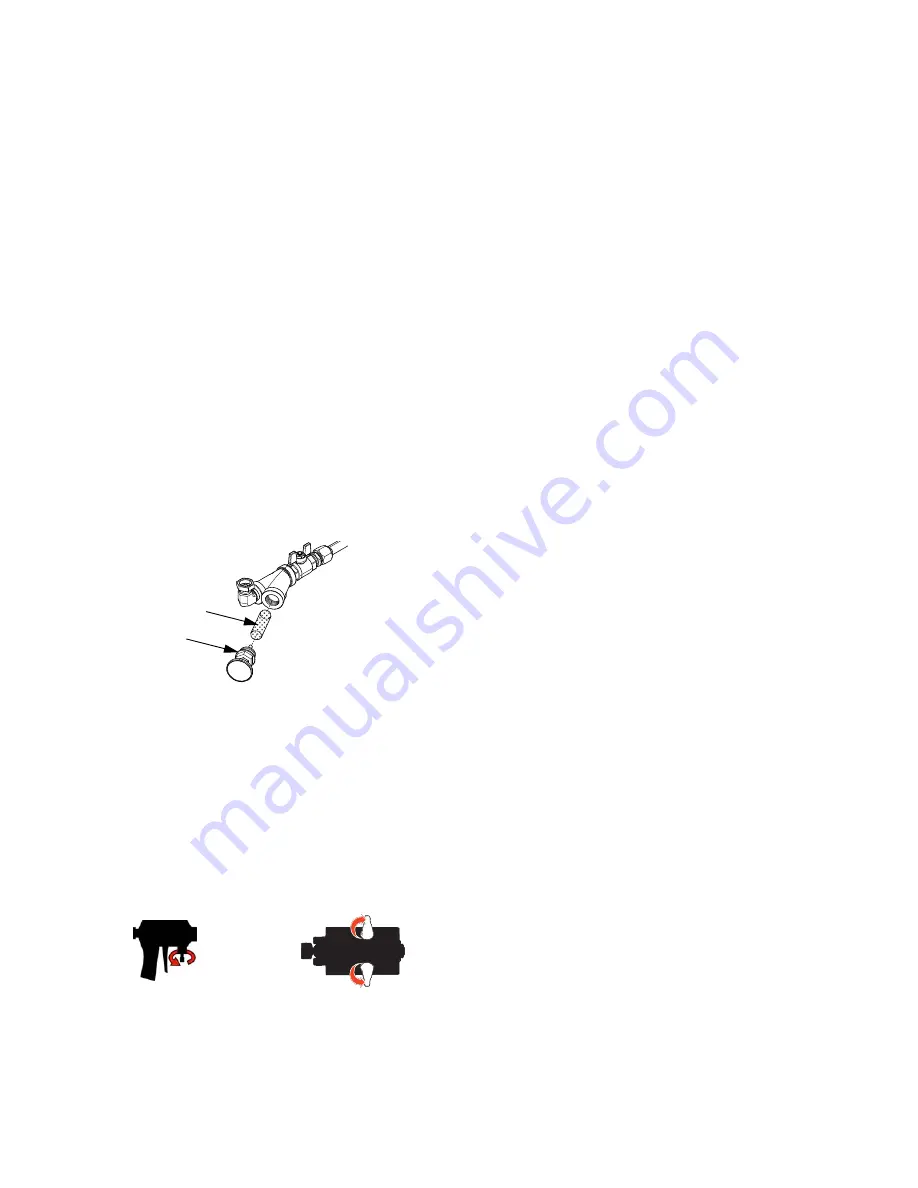

Remove plug (X) and clean fluid inlet strainer (S) as

needed. Always clean the fluid inlet strainers after

flushing.

•

Generally, flush if you will shutdown for more than

three days. Flush more often if material is moisture

sensitive and humidity is high in the storage area, or

if material may separate or settle out over time.

•

If using an impingement mix gun, close gun fluid

valves when not spraying. Doing this will keep the

internal parts of the gun cleaner and prevent cross-

over. Clean gun mix chamber ports and check valve

screens regularly. See gun manual.

•

If using an Fusion Air Purge impingement mix gun,

always grease the gun after use until purge air car-

ries grease mist out the front of the gun. Use Part

No. 117773 Grease. See gun manual.

X

S

ti21836a

Fusion

Probler