Maintenance

42

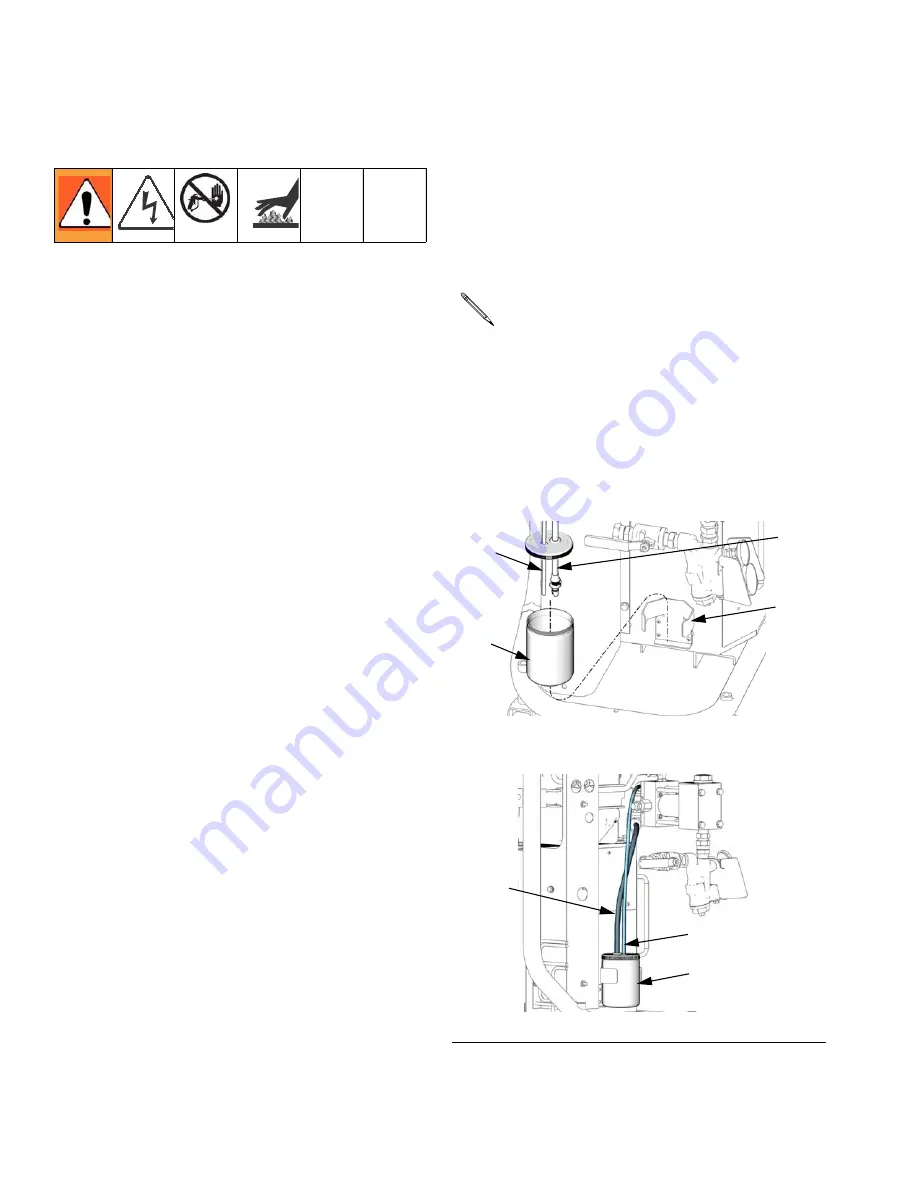

Pump Lubrication System

Check the condition of the ISO pump lubricant

daily. Change the lubricant if it becomes a gel,

its color darkens, or it becomes diluted with

isocyanate.

Gel formation is due to moisture absorption by

the pump lubricant. The interval between

changes depends on the environment in which

the equipment is operating. The pump lubrica-

tion system minimizes exposure to moisture,

but some contamination is still possible.

Lubricant discoloration is due to continual

seepage of small amounts of isocyanate past

the pump packings during operation. If the

packings are operating properly, lubricant

replacement due to discoloration should not be

necessary more often than every 3 or 4 weeks.

To change pump lubricant:

1. Relieve pressure, page 35.

2. Lift the lubricant reservoir (LR) out of the

bracket (RB) and remove the container

from the cap. Holding the cap over a suit-

able container, remove the check valve and

allow the lubricant to drain. Reattach the

check valve to the inlet hose. See F

IG

. 7.

3. Drain the reservoir and flush it with clean

lubricant.

4. When the reservoir is flushed clean, fill with

fresh lubricant.

5. Thread the reservoir onto the cap assembly

and place it in the bracket.

6. Push the larger diameter supply tube (ST)

approximately 1/3 of the way into the reser-

voir.

7. Push the smaller diameter return tube (RT)

into the reservoir until it reaches the bot-

tom.

8. The lubrication system is ready for opera-

tion. No priming is required.

Important:

The return tube (RT) must

reach the bottom of the reservoir, to

ensure that isocyanate crystals will set-

tle to the bottom and not be siphoned

into the supply tube (ST) and returned

to the pump.

F

IG

. 7. Pump Lubrication System

LR

RT

ST

RB

ti9911a

ti9887a

LR

ST

RT