Repair

309813B

25

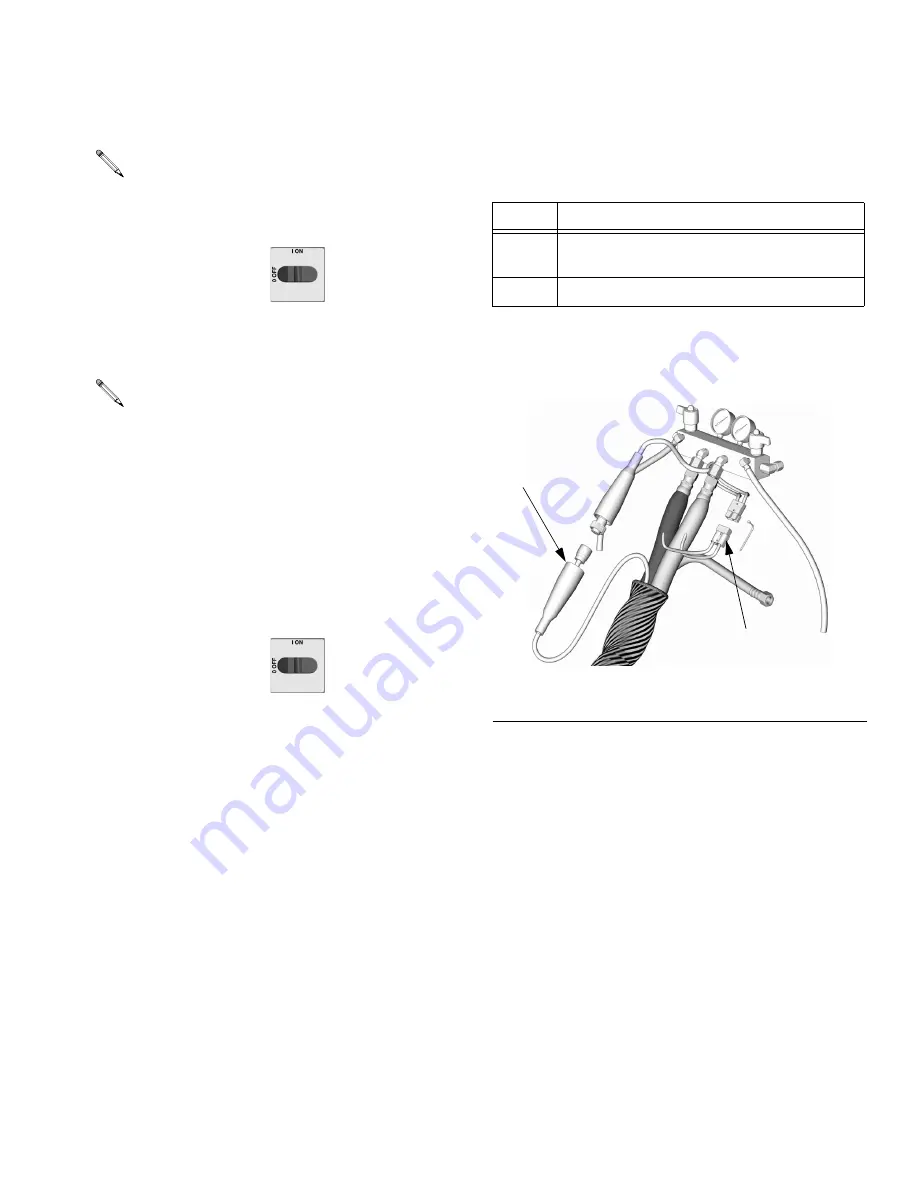

Heated Hose

Check Hose Connectors

2.

Relieve pressure, page 11.

3.

Disconnect hose electrical connector (D) at Reac-

tor, F

4.

Using an ohmmeter, check between the two termi-

nals of hose connector (D). There should be conti-

nuity.

5.

If hose fails test, retest at each length of hose,

including whip hose, until failure is isolated.

Check FTS Cables

2.

Relieve pressure, page 11.

3.

Disconnect FTS cable (F) at Reactor, F

4.

Test with ohmmeter between pins of cable connec-

tor.

5.

If cable fails test, retest at FTS, page 26.

Refer to the heated hose manual 309572 for hose

replacement parts.

1.

Turn main power OFF

. Disconnect power

supply.

Whip hose must be connected.

1.

Turn main power OFF

. Disconnect power

supply.

Pins

Result

1 to 2

approximately 35 ohms per 50 ft (15.2 m) of

hose, plus approximately 10 ohms for FTS

1 to 3

infinity (

∞

)

F

IG

. 7. Heated Hose

TI2726a

F

D