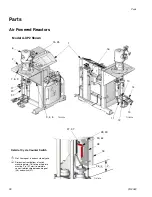

Parts

36

312408F

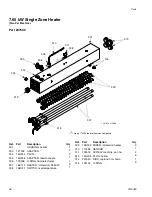

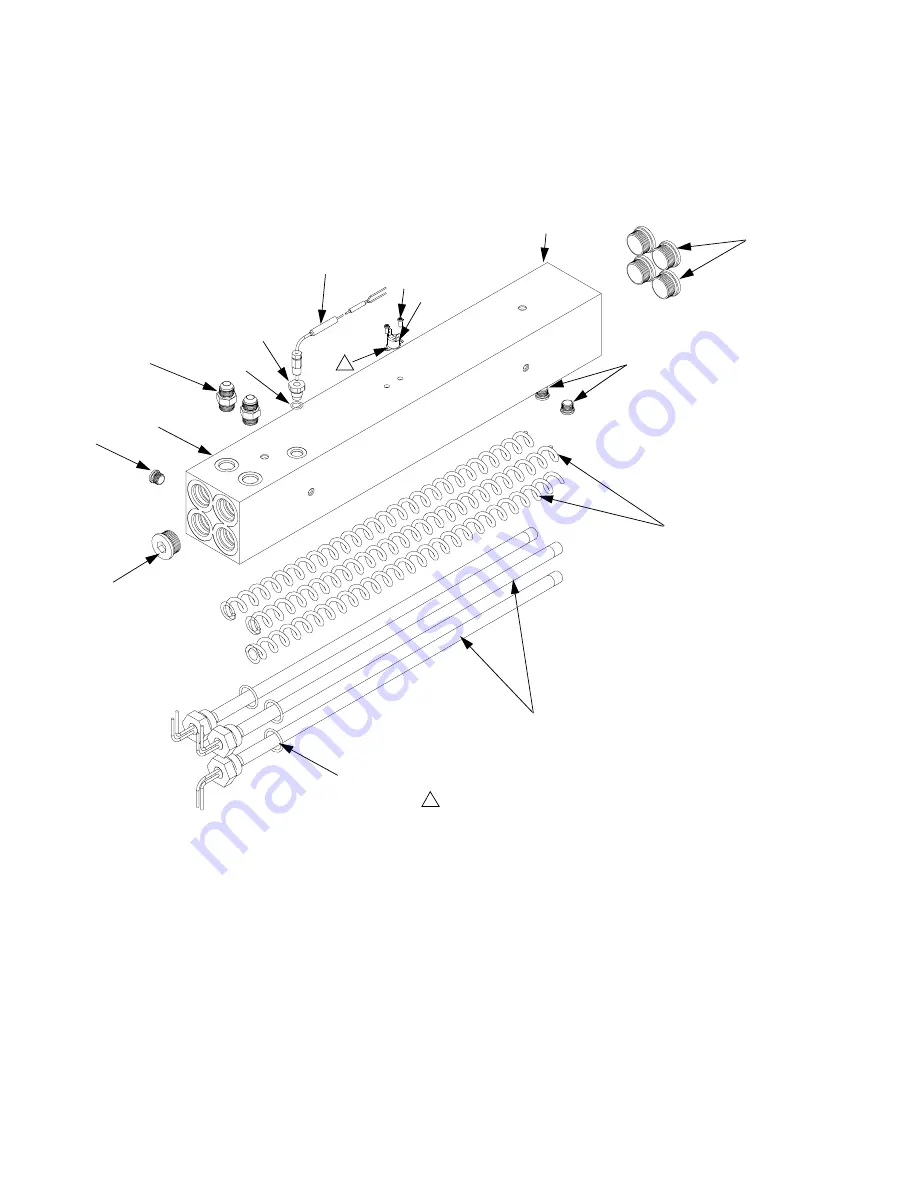

7.65 kW Single Zone Heater

(Two Per Machine)

Part 247509

303

301

304

307

308

310

311

305

306

1

304

313

313

r_247813_312066

Apply 110009 thermal heatsink compound.

1

309

314

315

Ref.

Part

Description

Qty

301

HOUSING, heater

1

303

121309 ADAPTER

2

304

15H304 PLUG

3

305

15H306 ADAPTER, thermocouple

1

306

120336 O-RING; fluoroelastomer

1

307

16A110 HEATER, immersion; 2550 W

3

308

15B137 SWITCH, overtemperature

1

309

15B135 MIXER, immersion heater

3

310

117484 SENSOR

1

311

100518 SCREW, machine, pan hd

2

313

15H305 PLUG, hollow

5

314

247520 DISC, rupture; not shown

1

315

124132 O-RING

3

Ref.

Part

Description

Qty

Summary of Contents for Reactor HT Series

Page 43: ...Parts 312408F 43 ...