Troubleshooting

312408F

13

Hose Heat System

Before performing any troubleshooting procedures:

1.

Relieve pressure, page 15.

2.

Turn main power OFF

.

3.

Allow equipment to cool.

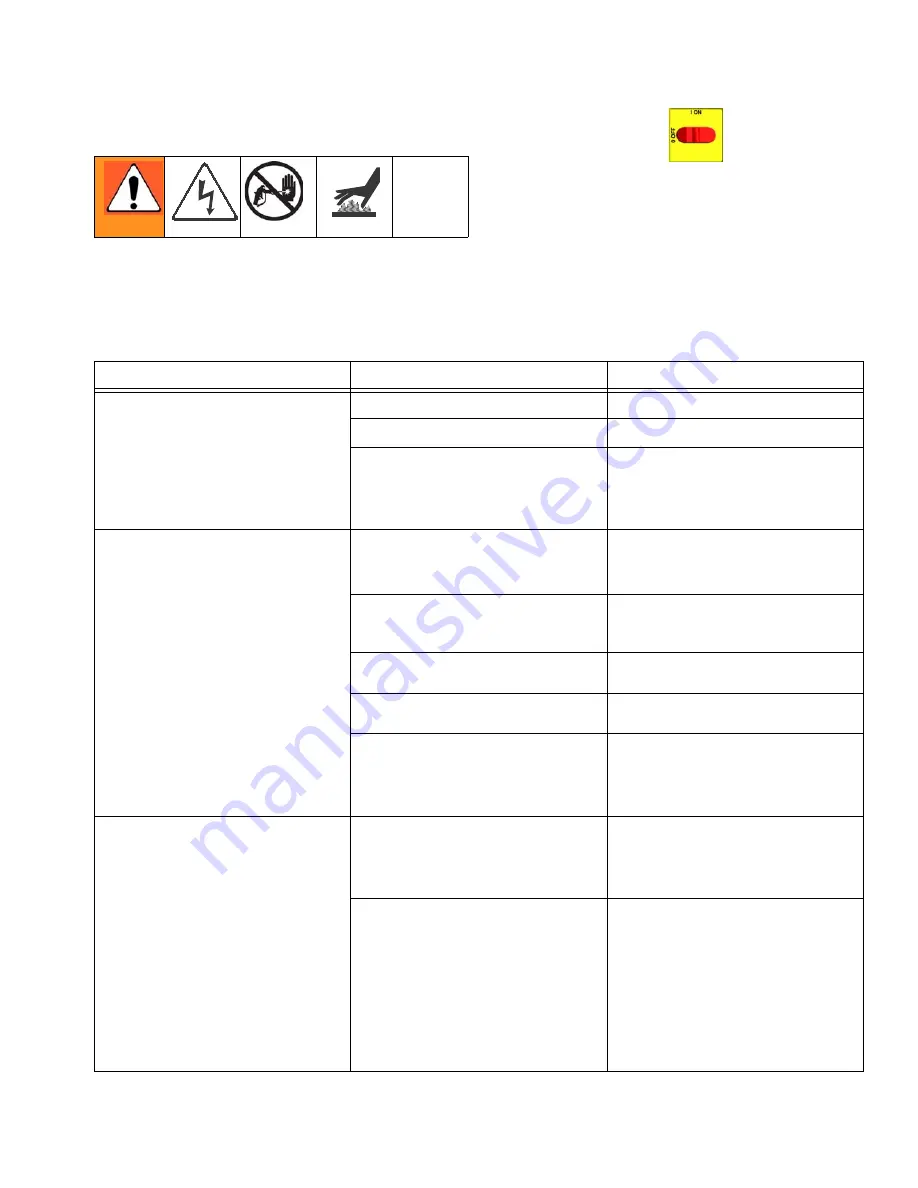

Problems

Try the recommended solutions in the order given for

each problem, to avoid unnecessary repairs. Also,

determine that all circuit breakers, switches, and con-

trols are properly set and wiring is correct before assum-

ing there is a problem.

PROBLEM

CAUSE

SOLUTION

Hose heats but heats slower than

usual or it does not reach tempera-

ture.

Ambient temperature is too cold.

Use auxiliary hose heat system.

FTS failed or not installed correctly.

Check FTS, page 9.

Low supply voltage.

Verify line voltage. Low line voltage

significantly reduces power available

to hose heat system, affecting longer

hose lengths.

Hose does not maintain temperature

while spraying.

A and B setpoints too low.

Increase A and B setpoints. Hose is

designed to maintain temperature,

not to increase it.

Ambient temperature is too cold.

Increase A and B setpoints to

increase fluid temperature and keep

it steady.

Flow too high.

Use smaller mix chamber. Decrease

pressure.

Hose was not fully preheated.

Wait for hose to heat to correct tem-

perature before spraying.

Low supply voltage.

Verify line voltage. Low line voltage

significantly reduces power available

to hose heat system, affecting longer

hose lengths.

Hose temperature exceeds setpoint.

A and/or B heaters are overheating

material.

Check primary heaters for either a

thermocouple problem or a failed ele-

ment attached to thermocouple, page

9.

Faulty thermocouple connections.

Verify that all FTS connections are

snug and that pins of connectors are

clean. Examine connection of ther-

mocouples to long green plug on

heater control board. Unplug and

re-plug thermocouple wires, cleaning

off any debris. Unplug and re-plug

long green connector on heater con-

trol board.

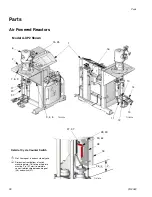

Summary of Contents for Reactor HT Series

Page 43: ...Parts 312408F 43 ...