Preparation

3A7026A

5

Preparation

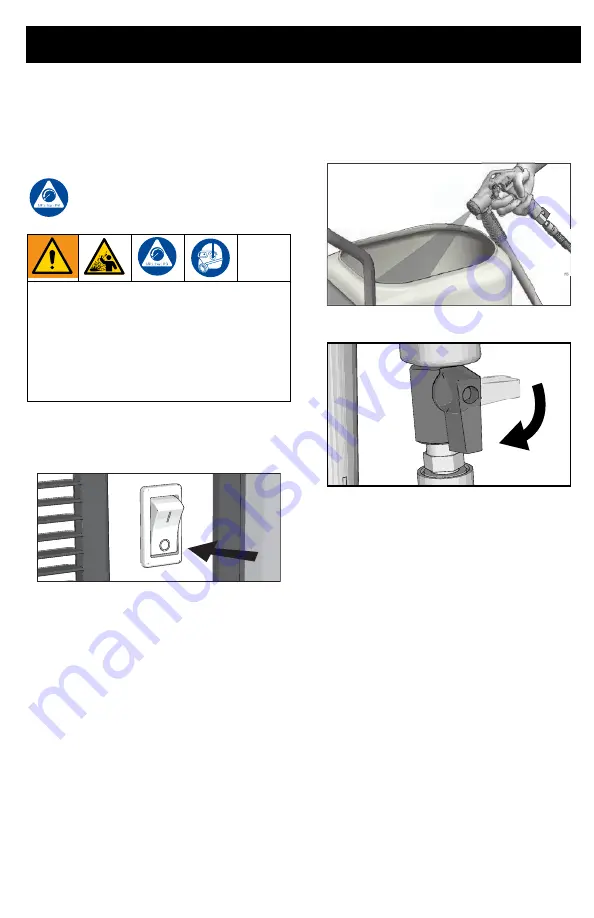

Pressure Relief Procedure

Follow the Pressure Relief

Procedure whenever you see this

symbol.

1.

Turn ON/OFF switch to the

OFF

position. Wait 7 seconds for power to

dissipate.

2.

Trigger gun into material hopper.

3.

Open air control valve.

4.

Open gun prime valve.

This equipment stays pressurized until

pressure is manually relieved. To help

prevent serious injury from pressurized

fluid or splashed fluid follow the

Pressure

Relief Procedure

whenever sprayer is

stopped and before sprayer is cleaned or

checked, and before equipment is

serviced.

ti27340a

ti27339a

ti27341a