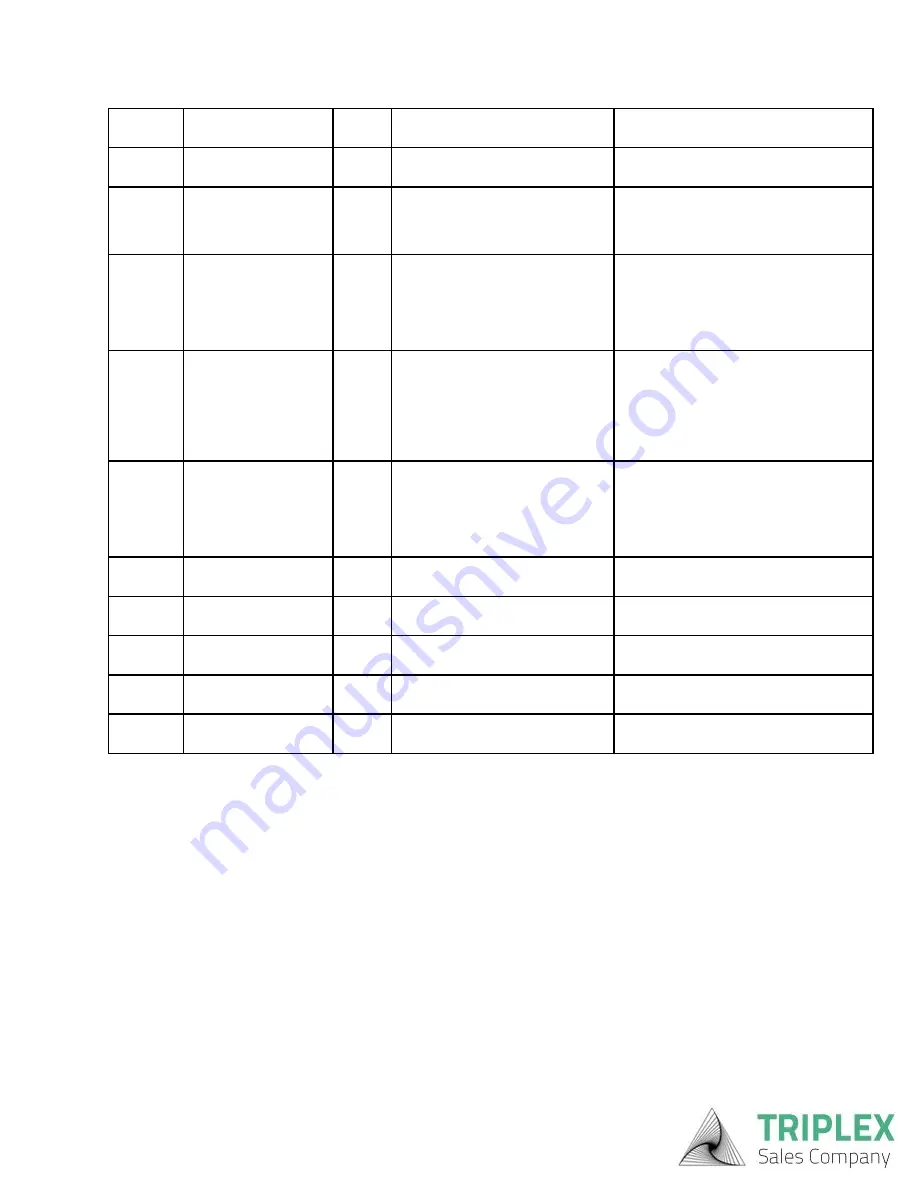

Electro-pneumatic Control Panel Display Screens

Event

Event

Event

Type

Type

Type

Event

Event

Event Description

Description

Description

Error

Error

Error

Code

Code

Code

Cause

Cause

Cause

Fix

Fix

Fix

Devia-

tion

Position sensor dirty

L2CL

Position sensor reflectivity value

is low.

Ensure the laser sensor and target

are clear of debris.

Devia-

tion

USB data format

error

WSU2

The data in the file targeted by a

USB import contains incorrectly

formatted data.

Verify data is formatted correctly.

No commas or new lines should be

inserted while modifying a file for

importing into the system.

Devia-

tion

USB file header error

WSU1

The information in the header

of the file targeted by a USB

import contains an incorrect or

incorrectly formatted Software

Part Number or Software

Version.

Verify Software Part Number and

Software Version and correct and

formatted correctly in the file header.

Devia-

tion

USB not connected

CCU0

A USB device is not connected

to the system.

Verify the USB device is compatible

with the system, formatted properly,

and inserted fully into one of the

USB ports on the back of the screen

unit. A USB device can take up to

10 seconds to be recognized by the

system once inserted.

Devia-

tion

USB operation failed

WXU0

A USB import or export

command was not able to be

completed: an unspecified error

occurred during the operation.

check that the USB device is fully

inserted into the USB ports on the

back of the screen unit. If importing,

check formatting of data in files and

remove any unnecessary files from

the directory.

Advisory

USB Export

Successful

EQUE

USB Export operation completed

successfully.

N/A

Advisory

USB Import

Successful

EQUI

USB Import operation

completed successfully.

N/A

Record

System

Depressurization

P010

A depressurization sequence

was completed.

N/A

Record

System Startup

ELC0

The system started up and the

boot sequence completed.

N/A

Record

System Time

Changed

ECT0

The system time was changed

by more than one minute.

N/A

* Modules must be installed in the following order, from left to right:

X20BC1083

X20PS9400

X20CM8281

X20DS438A

X20AO2622

X20DO8322

3A5416L

51

Triplex Sales

1-847-839-8442

www.triplexsales.com