ti29755a

Start Up

3A7649A

11

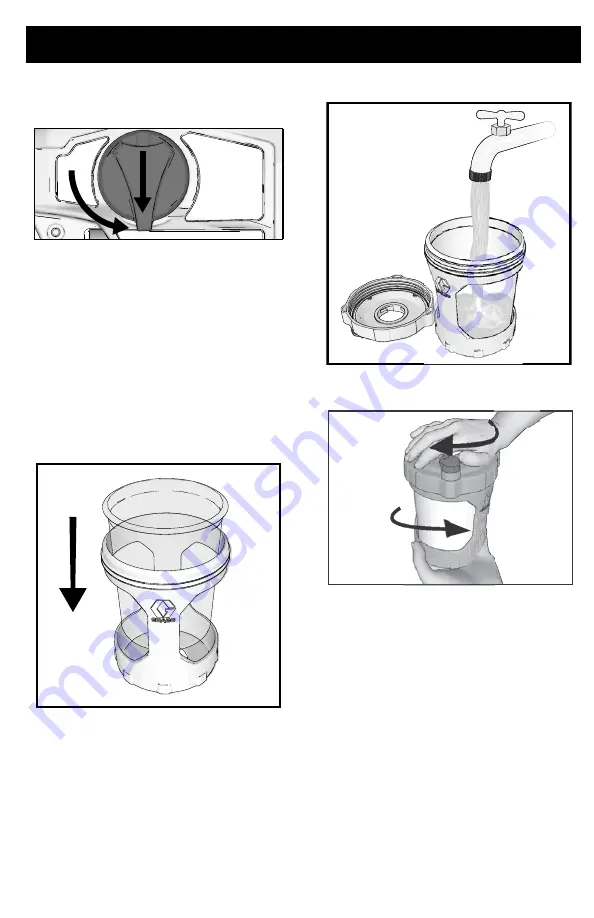

2.

Turn the Prime Pump/Spray Knob

downward to PRIME position to relieve

pressure.

Flushing a New Sprayer

This sprayer arrives from the factory with a

small amount of test fluid in the system.

It is

important that you flush this fluid from the

sprayer before using for the first time.

See

23, for additional information when using

disinfectants with alcohol active ingredients,

or other flammable disinfectants.

1.

Install a FlexLiner into the Cup Support.

2.

Fill FlexLiner with warm water.

3.

Firmly tighten the Cup Lid onto the Cup

Support to achieve an airtight seal.

4.

Install the cup assembly onto the sprayer

as follows:

a.

Align VacuValve Cap on the Cup

Lid with the Prime Pump/Spray

Knob.

ti23361a

ti23383a

ti29719a