Operation

4

Operation

Pressure Relief Procedure

1.

Turn off gun air supply.

2.

Trigger the gun to relieve pressure.

Flushing

Flush before using the equipment, before changing

colors, and when you are done spraying. Use solvent

that is compatible with gun wetted parts and fluid that

will be sprayed. Flush at lowest possible pressure.

NOTE:

Refer to

, page 5,

to comply with air quality laws if applicable.

1.

Follow

.

2.

Dispose of any paint in cup.

3.

Fill cup with small amount of solvent.

4.

Spray into grounded metal waste container until

equipment is clean.

5.

Follow

.

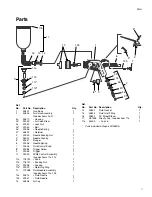

Spraying

1.

Fill cup (17) with material. Do not fill past full mark-

ings on cup.

2.

Slowly adjust gun air pressure while fully triggering

the gun until you have the desired atomization.

3.

Adjust the pattern size and shape with the spray

width adjustment knob (11). Turn knob clockwise to

reduce pattern size and counterclockwise to

increase it.

NOTE: See

Troubleshooting

guide if you experience

an irregular pattern.

4.

Fluid control knob (7) is factory set for maximum

needle trigger travel and material flow. To decrease

needle/trigger travel and decrease fluid flow, turn

knob clockwise.

Follow

when you stop

spraying and before cleaning, checking, or servicing

equipment. Read warnings, page 2.

NOTICE

Excessive atomizing air pressure can increase

over-spray, reduce transfer efficiency, result in a poor

quality finish from dry spray.

Regulatory agencies in certain states prohibit the

operation of a spray gun above 10 psi (69 kPa, 0.7 bar)

atomizing air cap pressure.