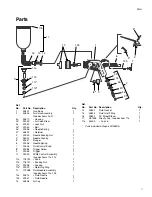

Troubleshooting

6

Troubleshooting

Technical Data

Maximum Air Inlet Pressure:

50 psi (345 kPa, 3.4 bar)

Maximum HVLP Compliant Air Pressure:

40 psi (276 kPa,

2.8 bar) - delivers 10 psi (69 kPa, 0.7 bar) spraying pressure at

air cap

Wetted Parts:

stainless steel, aluminum, L/D polyethylene

Air Consumption:

2.8 CFM at 40 psi (276 kPa, 2.8 bar)

Spray Gun:

•

1/4 npsm (R1/4-19) air inlet

•

1/4 npsm fluid inlet

•

Weight - 8 oz. (227 grams)

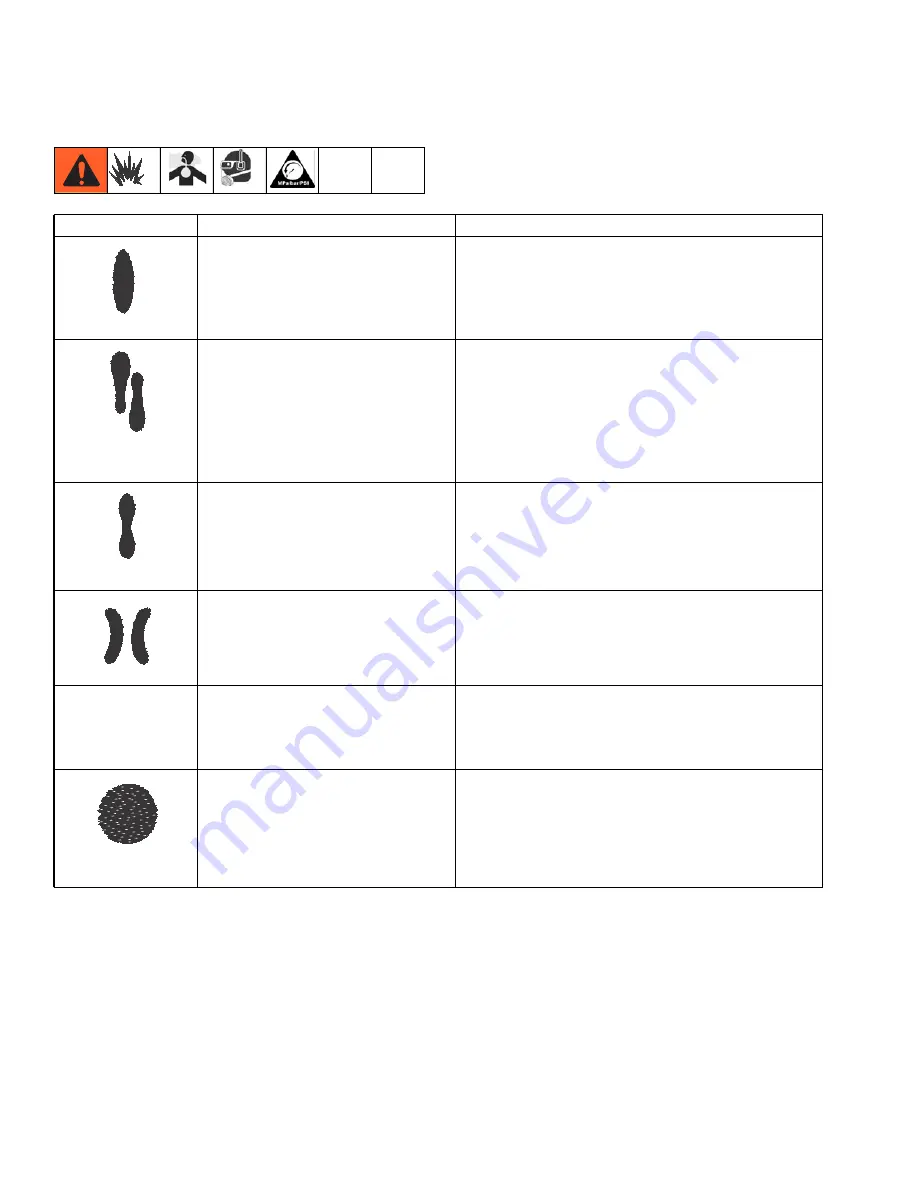

Problem

Cause

Solution

Normal pattern

No action necessary

Dirty or damaged air cap or fluid

nozzle.

Rotate air cap 180°.

If pattern follows air cap,

problem is in air cap. Clean

and inspect. If pattern is not corrected, replace air cap.

If pattern does not follow the air cap,

the problem is

with the fluid nozzle. Clean and inspect the nozzle. If

the pattern is not corrected, replace nozzle.

Pressure too high for viscosity of

material being sprayed.

a. Reduce air pressure.

b. Increase material viscosity

c. Correct pattern by narrowing fan size with spray

width adjustment knob.

Dirty or distorted air horn holes.

Rotate air cap 180°.

If pattern follows air cap,

problem is in air cap. Clean

and inspect. If pattern is not corrected, replace air cap.

Will not spray.

a. Cup is not tight

a. Tighten cup lid.

b. Cup empty.

c. Fill cup.

d. Air cap not seated.

e. Turn spray width adjustment knob fully counter-

clockwise. Tighten air cap.

a. Air pressure too low.

b. Gun held too close to surface.

a. Increase air pressure.

b. Hold gun about 6-8 inches (150-200 mm) from sur-

face.

Right

Wrong

Heavy top or

bottom pattern

Wrong

Split pattern

Wrong

Wrong

Heavy pattern or

orange peel