Setup/Startup

22

3A8108A

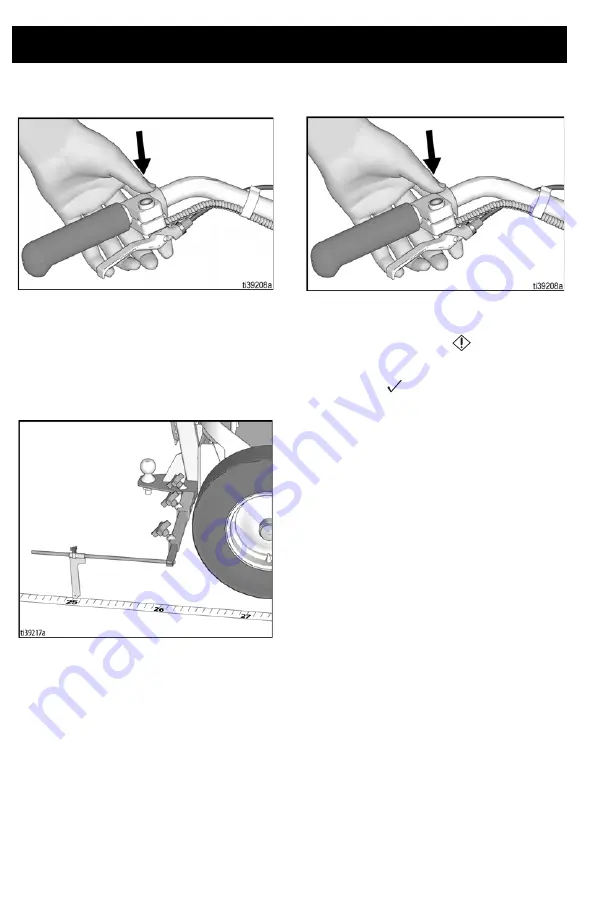

7.

Press and release tape application

button to start calibration.

8.

Move TapeLazer forward. Keep guide

on steel tape.

9.

Stop when guide aligns with 25 ft mark

on steel tape (a total traveled distance of

24 ft.), or to whatever distance you

entered on the screen.

10. Press and release tape application

button to complete calibration.

NOTE:

Calibration is

NOT

complete when

the exclamation symbol

is displayed.

NOTE:

Calibration is finished when the check

mark symbol

is displayed.

11. Calibration is now complete.

Summary of Contents for TapeLazer HP Automatic

Page 15: ...Setup Startup 3A8108A 15 7 Using a 1 4 in Allen wrench tighten bolts ...

Page 25: ...Operation 3A8108A 25 TapeLazer LiveLook Display ...

Page 51: ...Troubleshooting 3A8108A 51 Solenoid Ports Reference ...

Page 52: ...Parts 52 3A8108A Parts TapeLazer Parts ...

Page 54: ...Parts 54 3A8108A Front End Parts ...

Page 56: ...Parts 56 3A8108A Carriage Applicator Parts ...

Page 58: ...Parts 58 3A8108A Display Unit Parts ...

Page 60: ...Parts 60 3A8108A Additional Parts ...

Page 62: ...Air Line Schematic 62 3A8108A Air Line Schematic ...

Page 64: ...Wiring Diagram 64 3A8108A Wiring Diagram ...

Page 65: ...Universal Symbols Key 3A8108A 65 Universal Symbols Key ...