Troubleshooting

3A8108A

49

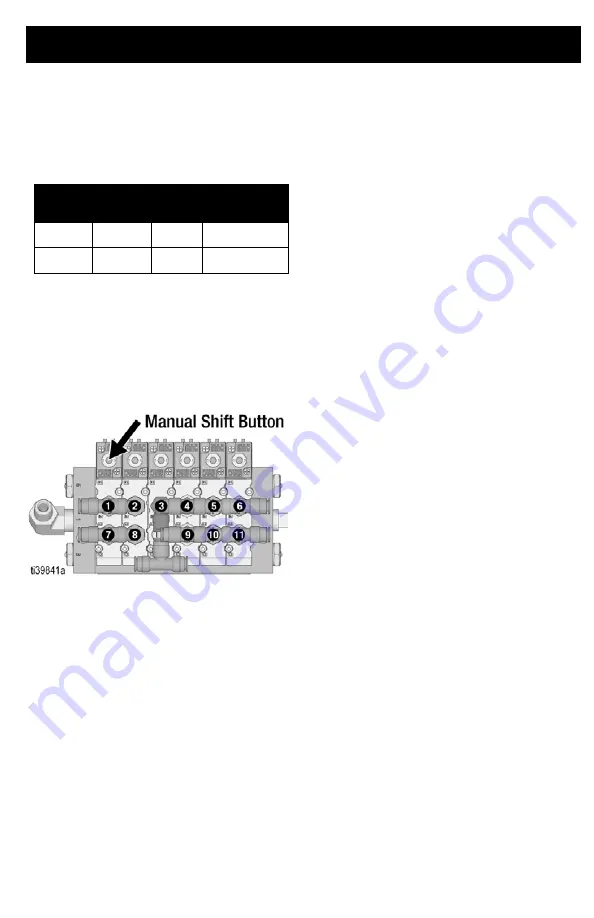

To Check if Solenoids are

Functioning Properly

1.

Run unit in diagnostics screen under the

following conditions, see

2.

Checked ports should not have any air

flowing from them. If they do, the

solenoid manifold is not functioning

correctly and may need to be replaced.

Try to shift the solenoid by depressing

the ‘manual shift button’ to dislodge a

stuck valve. If that does not work, the

solenoid manifold must be replaced.

System is not holding pressure/not

generating pressure

This indicates that there is a leak in the

system. This procedure details how to find

and fix the leak.

NOTE:

The system will bypass air through

unloader valve once at 145 psi.

1.

Check main pressure relief valve to

make sure it is closed and not leaking air.

2.

Check pressure relief lever on the

unloader valve to make sure it is in the

closed position and not leaking air.

3.

Run unit to determine if the air

compressor is outputting air. Open the

pressure relief valve to check for air flow.

Also look for the compressor fan to be in

motion while the unit is running.

a.

Compressor is outputting air:

there is a leak elsewhere in the

system. Proceed with step 4.

b.

Compressor is not outputting

air:

compressor has failed.

Replace compressor and follow

recommended maintenance

intervals to prevent future failure.

4.

Close off system by turning pressure

relief valve shut and check for external

leaks. There should be no air leaking out

of any external piece of the equipment,

besides the unloader valve. Potential

leak points to check:

a.

Air lines: If an air line is damaged

(kinked, torn) replace with

replacement tube and install

properly to avoid future damage

and kinking. If air lines are loose

from the push connect fitting,

reconnect and ensure that hose

marking is flush with push to

connect collet.

b.

Fittings: Damaged fittings will need

to be replaced. If a loose fitting is

causing the issue, tighten the fitting

to stop the leak.

c.

Manifold Exhaust valves: If air is

leaking from exhaust valves on

manifold, this is usually indicative

of an air cylinder failure, NOT a

solenoid failure. Follow procedure

outlined below to thoroughly check

for air cylinder leaks.

Output

‘1’

Output

‘2’

Output

‘C’

Ports to unplug

and check

Off

Off

Off

1, 2, 3, 4, 5, 6

On

On

On

7, 8, 9, 10, 11

Summary of Contents for TapeLazer HP Automatic

Page 15: ...Setup Startup 3A8108A 15 7 Using a 1 4 in Allen wrench tighten bolts ...

Page 25: ...Operation 3A8108A 25 TapeLazer LiveLook Display ...

Page 51: ...Troubleshooting 3A8108A 51 Solenoid Ports Reference ...

Page 52: ...Parts 52 3A8108A Parts TapeLazer Parts ...

Page 54: ...Parts 54 3A8108A Front End Parts ...

Page 56: ...Parts 56 3A8108A Carriage Applicator Parts ...

Page 58: ...Parts 58 3A8108A Display Unit Parts ...

Page 60: ...Parts 60 3A8108A Additional Parts ...

Page 62: ...Air Line Schematic 62 3A8108A Air Line Schematic ...

Page 64: ...Wiring Diagram 64 3A8108A Wiring Diagram ...

Page 65: ...Universal Symbols Key 3A8108A 65 Universal Symbols Key ...