19

309916

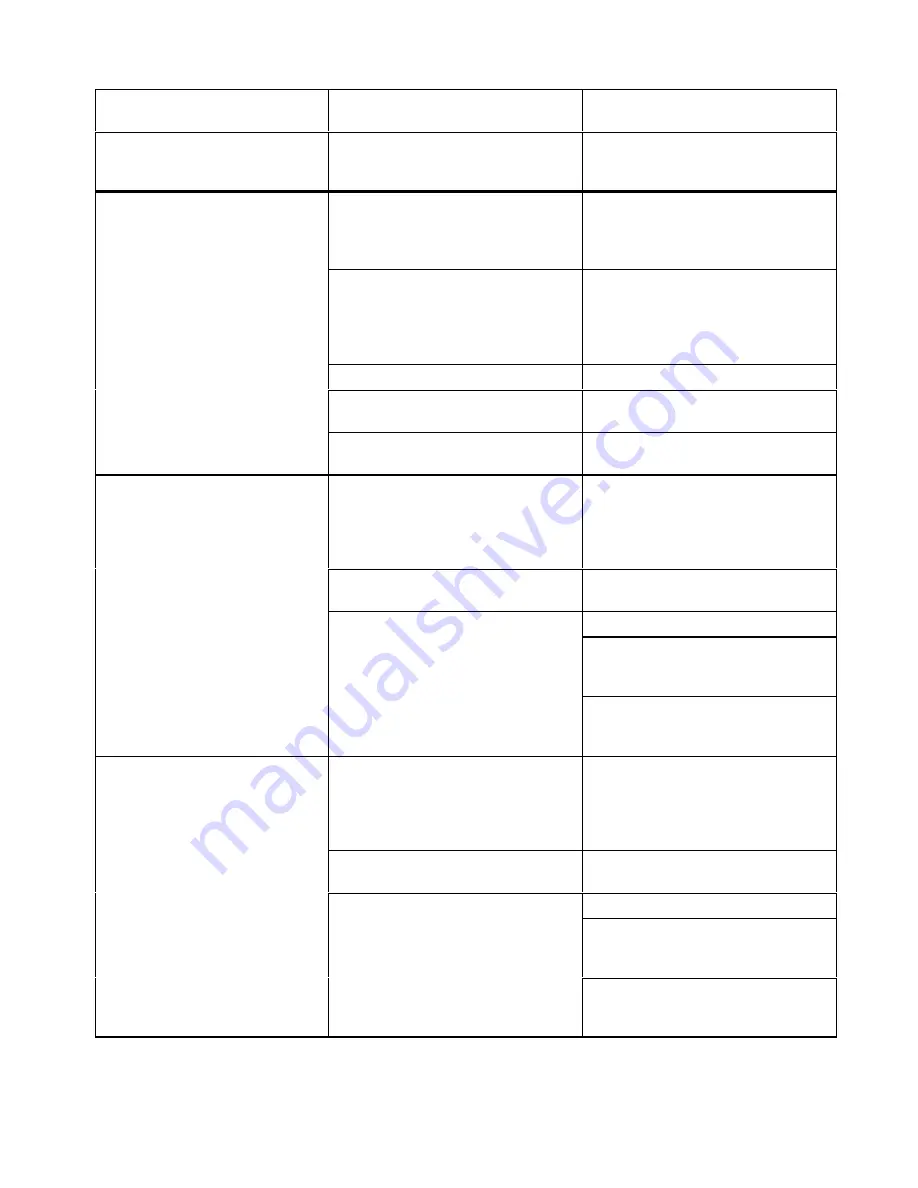

Troubleshooting

Pump stops pumping

Pump in need of repair

See texture pump instruction

manual 308479.

Pulsing or surging material

Triggering too fast

Slowly squeeze trigger to fully open

position while moving gun quickly in a

circular motion.

Speed of application too slow

Not enough air pressure to pump

Shut off air at the gun, and increase

air pressure to the pump to maxi-

mum. Turn regulator clockwise to

increase.

Material too thick

Material must be mixed thoroughly

to a consistency that immediately

folds back in as you draw your fin-

ger through the surface of the ma-

terial.

Nozzle too small

Increase nozzle size.

Hose plugged or too small.

Relieve pressure

, page 6. Clean

hose, or try a 1–1/4 in. hose.

Pump in need of repair

See texture pump instruction

manual 308479.

Pattern too fine or too much

overspray

Material too thin

Thicken material. Material must be

mixed thoroughly to a consistency

that immediately folds back in as

you draw your finger through the

surface of the material.

Air pressure at gun too high

Decrease air to gun at gun fitting

and/or regulator.

Fluid delivery too low

Increase nozzle size.

Increase air pressure to pump, or

decrease air to gun at gun fitting

and/or regulator.

Turn fluid knob out on gun. See

Spray Techniques

in Operation

Manual 309915.

Pattern too coarse

Material too thick

Thin material. Material must be

mixed thoroughly to a consistency

that immediately folds back in as

you draw your finger through the

surface of the material.

Air pressure at gun too low

Increase air to gun at gun fitting

and/or regulator.

Fluid delivery too high

Decrease nozzle size.

Decrease air pressure to pump, or

increase air to gun at gun fitting

and/or regulator.

Turn fluid knob in on gun. See

Spray Techniques

in Operation

Manual 309915.