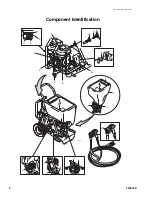

Component Identification

309915D

5

Component Identification

* Reference numbers used in gun illustrations coincide with reference numbers shown in gun manual 308878

A

Gas Tank

B

Fuel Valve

C

Choke

D

Throttle Lever

E

Engine ON/OFF Switch

F

Nozzle Storage

G

Hopper

H

Hopper Quick Connect

J

Diaphragm Pump

K

Material Outlet Option 1

L

Material Outlet Option 2

M

Air Cooler

N

Gun Air Outlet Quick Connect

P

Air Filter (both sides)

Q

Air Line Quick Connect

R

Engine Starter Cord

S

Motor Lock Knob

T

Material (Pump) Air Pressure Gage and Control Knob

U

Gun Air Pressure Gage and Control Knob

V

Sprayer Quick Connect Air In and Air ON/OFF Valve

W

Pressure Unloader

Y

Gun (see manual 308878)*

Z

Compressor Power Pack