Setup

Setup

Setup

Tools

Tools

Tools Required

Required

Required

• Two adjustable wrenches

• Non-sparking hammer or plastic mallet

1.

Ground sprayer. See

2.

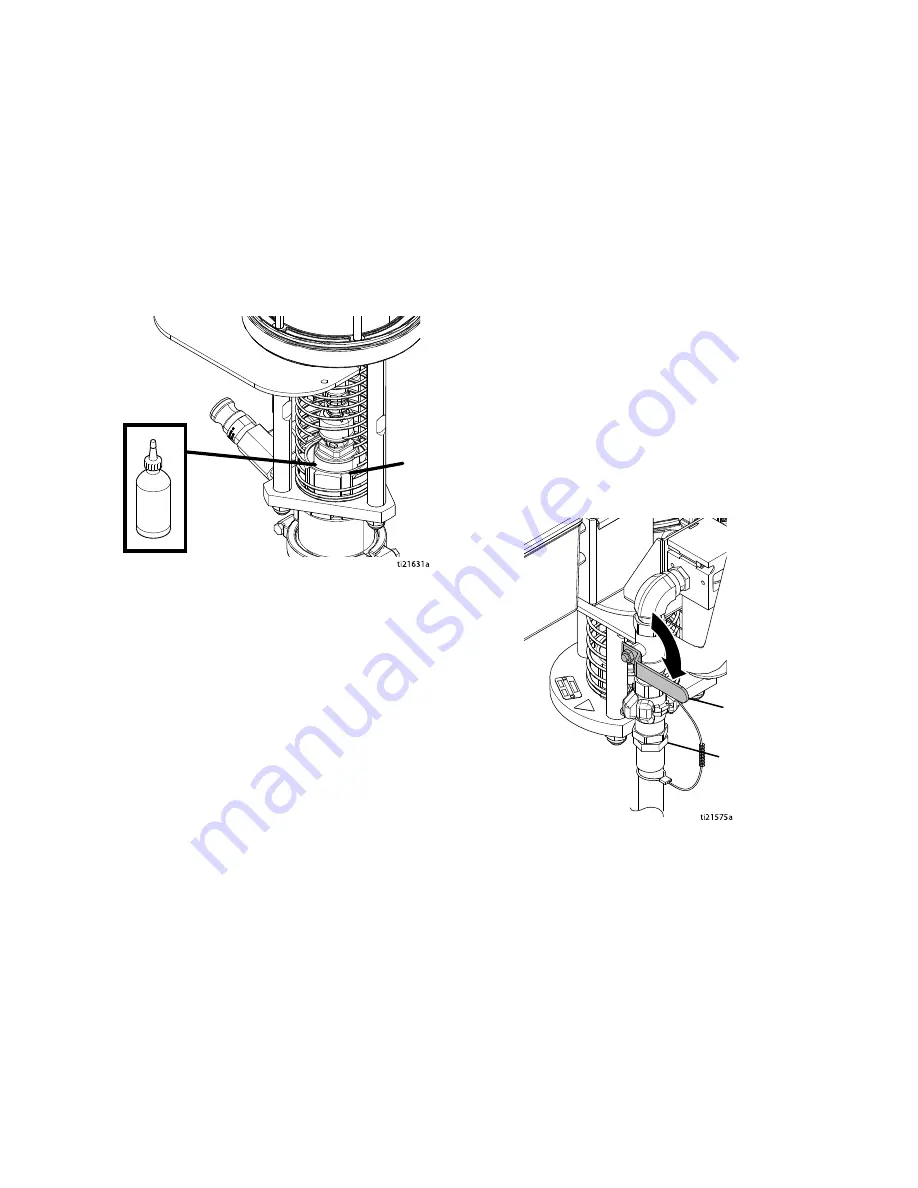

Check Throat Seal Liquid (TSL) level in packing

nut (R). Fill 1/2 full with TSL.

R

ti21631a

Figure 7

3.

Attach 1 in. x 25 ft electrically conductive fluid

hose to pump outlet.

Note

NOTE:

NOTE:

NOTE: The 3/4 in. hose will be

connected to the end of the 1 in. hose at

the factory.

4.

Attach large air line from hose bundle to main air

quick disconnect (N). See

.

5.

Attach small air tube from hose bundle to motor

pilot signal (X). Use wrench to secure air tube in

place. See

6.

Attach 3/4 in. hose to applicator fluid inlet.

7.

Attach large air line from hose bundle to applicator

quick disconnect (W). See

8.

Attach small air tube from hose bundle to

air motor pilot ball valve (G) on applicator.

Use wrench to secure air tube in place. See

9.

Wrap blue, velcro, camlock retaining straps

around each camlock connection to secure.

Note

NOTE:

NOTE:

NOTE: This includes the two camlocks

between the hopper and pump lower, the

camlock at the pump outlet, the camlocks

on the fluid hoses, and the camlock on

the applicator inlet. The retaining straps

should be tight and must not be able to

slide off camlock.

10. Going from applicator back to the system, wrap a

zip tie around all hoses every few feet to secure

them together.

11. Connect air supply hose:

a.

Close bleed type master air valve (B).

b.

Expand end of whip check cable (Y) and

slide it over the end of your air hose.

c.

Connect air supply hose to 3/4 npt(f) claw

fittings air inlet (A).

d.

Install safety clips in claw fittings.

B

A

ti21575a

Figure 8

12. Wet out the system with material flushing agent

before using. See

.

14

332612C