Flush

Flush

Flush

NOTICE

NOTICE

NOTICE

Failure to flush prior to material curing in the

system will result in damage to system and may

require replacement of all system parts in contact

with the material.

NOTICE

NOTICE

NOTICE

If the zero cavity pressure relief valve has been

used to relieve pressure, the valve must be flushed

to prevent material hardening in zero cavity relief

valve. If that is not sufficient, remove, disassemble,

and clean the valve then reinstall.

• Flush if the materials in the system are about to

reach their cure time.

• Flush any time the flow rate starts to decrease as

this is a sign that material is starting to thicken and

cure.

• Always flush the system at least twice, draining

all material flushing agent between flushes then

replacing with clean material flushing agent.

• For some mortars, it is recommended to flush

every 3 - 5 kits. Others can run continuously

without flushing. See material manufacturer

recommendation.

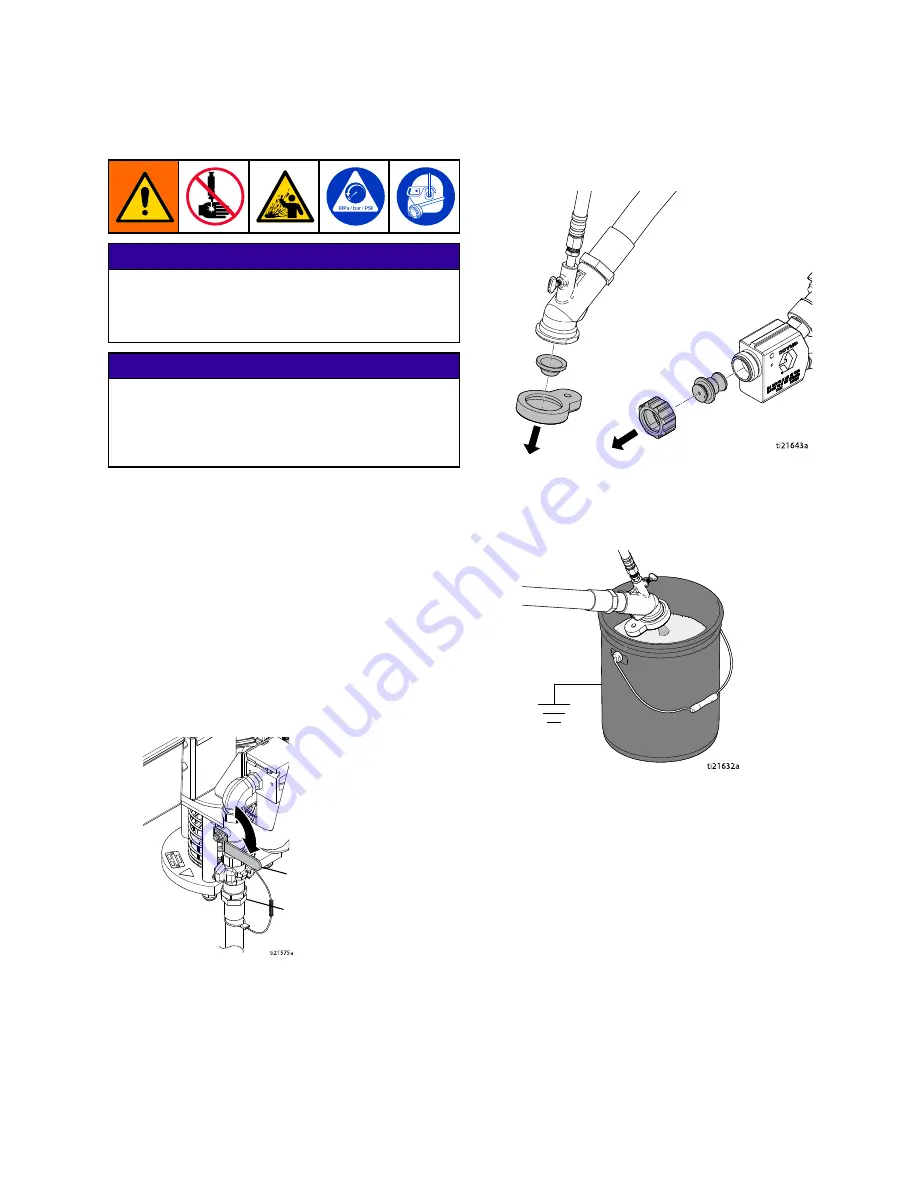

1.

Close the bleed type master air valve (B).

B

A

ti21575a

Figure 31

2.

Remove applicator tip and retainer.

ti21643a

Figure 32

3.

Place applicator outlet in a waste container. The

waste container must be large enough to hold

all dispensed material.

ti21632a

Figure 33

4.

With air assist air flowing, open the material ball

valve (V) on the base of the applicator.

5.

Open the pilot ball valve (G) located on base of

applicator.

332612C

27