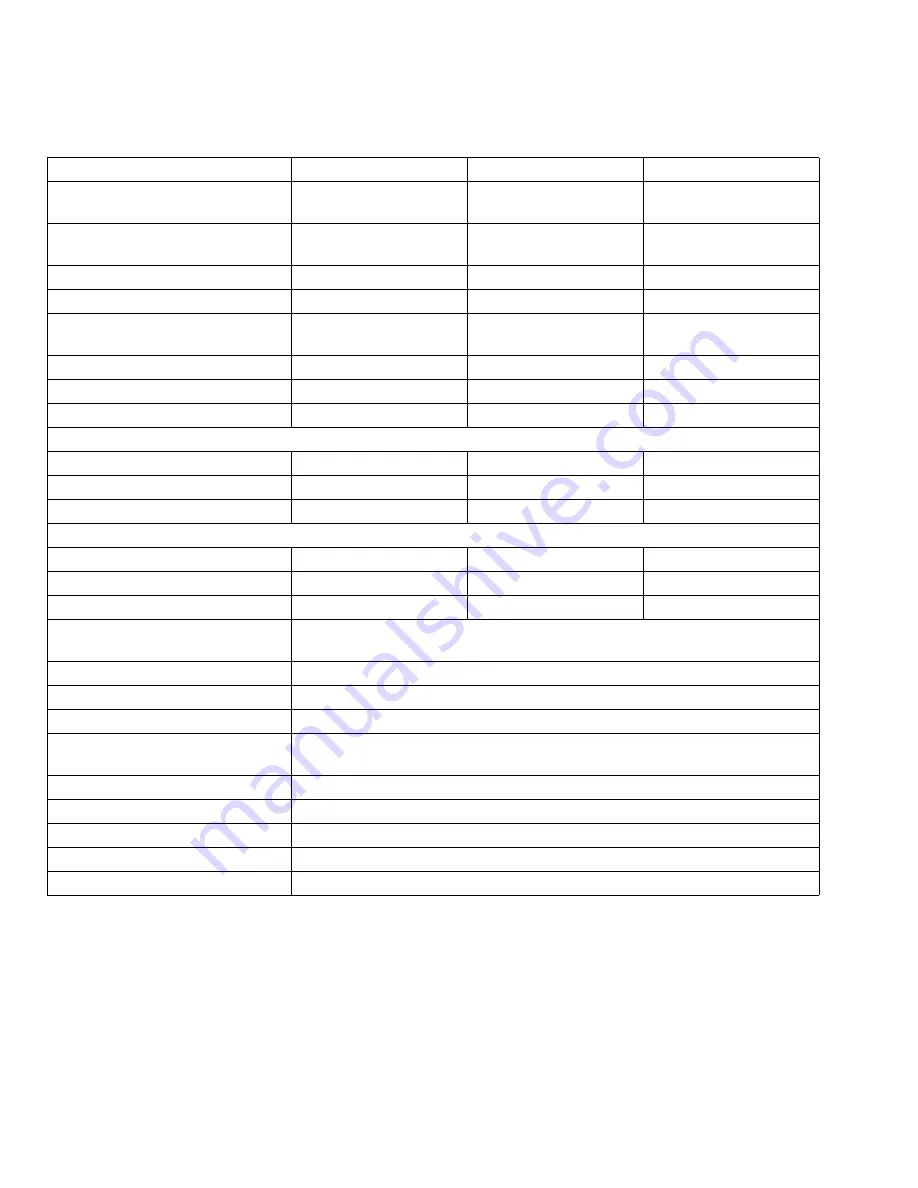

Technical Data

34

313381L

Technical Data

Project Painter

Tradeworks 150

Tradeworks 170

Working pressure range

0-2800 psi

(0-19 MPa, 0-193 bar)

0-3000 psi

(0-21 MPa, 0-207 bar)

0-3000 psi

(0-21 MPa, 0-207 bar)

Electric motor

7.0A

(open frame, universal)

9.0A

(open frame, universal)

9.0A

(open frame, universal)

Operating horsepower

3/8

1/2

5/8

Maximum delivery (with tip)

0.24 gpm (0.91 lpm)

0.27 gpm (1.02 lpm)

0.31 gpm (1.17 lpm)

Paint hose

1/4 in. x 25 ft

(6.4 mm x 7.5 m)

1/4 in. x 25 ft

(6.4 mm x 7.5 m)

1/4 in. x 50 ft

(6.4 mm x 15 m)

Maximum tip hole size

0.015 in. (0.38 mm)

0.015 in. (0.38 mm)

0.017 in. (0.43 mm)

Weight, sprayer only

10 lb (4.5 kg)

13.3 lb (6.0 kg)

23.3 lb (10.6 kg)

Weight, sprayer, hose & gun

13.2 lb (5.9 kg)

16.5 lb (7.5 kg)

26.5 lb (12.0 kg)

Dimensions (Upright):

Length

13.6 in. (34.5 cm)

13.7 in. (34.8 cm)

19.3 in. (49.0 cm)

Width

11.1 in. (28.1 cm)

16.2 in. (41.1 cm)

15.3 in. (38.9 cm)

Height

17.8 in. (45.2 cm)

18.2 in. (46.3 cm)

37.0 in. (94.0 cm)

Dimensions (Folded):

Length

N/A

N/A

19.3 in. (49.0 cm)

Width

N/A

N/A

15.3 in. (38.9 cm)

Height

N/A

N/A

29.2 in. (74.2 cm)

Power cord

18 AWG, 3-wire,

6 ft (1.8 m)

Fluid inlet fitting

3/4 in. internal thread (standard garden hose thread)

Fluid outlet fitting

1/4 NPSM external thread

Inlet screen (on suction tube)

35 mesh (450 micron)

Wetted parts, pump & hose

stainless steel, brass, leather, ultra-high molecular weight polyethylene

(UHMWPE), carbide, nylon, aluminum, PVC, polypropylene, fluroelastomer

Wetted parts, gun

aluminum, brass, carbide, nylon, plated steel, stainless steel, UHMWPE, zinc

Generator requirement

1500 Watt minimum

Electrical power requirement

120 Vac, 60 Hz, 15A, 1 phase

Storage temperature range

-30° to 160°F (-35° to 71°C)

Operating temperature range

40° to 115°F (4° to 46°C)

When pump is stored with non-freezing fluid. Pump damage will occur if water or latex paint freezes in

pump.

Damage to plastic parts may result if impact occurs in low temperature conditions.

Changes in paint viscosity at very low or very high temperatures can affect sprayer performance.

Summary of Contents for Tradeworks 150

Page 35: ...Notes 313381L 35 Notes ...