24

309303

Technical Data

Category

Data

Maximum fluid working pressure

115 psi (0.8 MPa, 8.0 bar)

Air pressure operating range

12 to 115 psi (.08 to 0.8 MPa, 0.8 to 8.0 bar)

Ratio

1:1

Maximum free flow delivery

8.5 gal./min (32 l/min)

Operating temperature range

50 to 176

_

C (10 to 80

_

C)

Maximum suction lift

16 ft (4.8 m) dry; 22 ft (6.7 m) wet

Weight

Part No. 233500:

9 lb (4 kg)

Part No. 233501:

14 lb (6.4 kg)

Wetted parts

Part No. 233500:

Aluminum, Stainless Steel, Acetal, Nylon,

r

Part No. 233501:

Stainless Steel, Acetal, Nylon,

r

r

and Viton

r

Sound Pressure Levels in dB(A)*

(measured at 1 m from unit)

Input Air Pressures

Sound Pressure

40 psi (0.28 MPa, 2.8 bar)

69.1

60 psi (0.42 MPa, 4.2 bar)

72.1

Sound Power Levels in dB(A)*

(tested in accordance with ISO 3744)

Input Air Pressures

Sound Power

40 psi (0.28 MPa, 2.8 bar)

80.8

60 psi (0.42 MPa, 4.2 bar)

83.7

0

1

2

3

4

5

6

7

8

0

1

2

3

4

5

6

7

8

24

47

71

cycles per minute

gpm

l/min

22.8

7.6 11.4

A

B

C

118

30.4

94

141 165 188

3.8

15.2 19.0

26.6

D

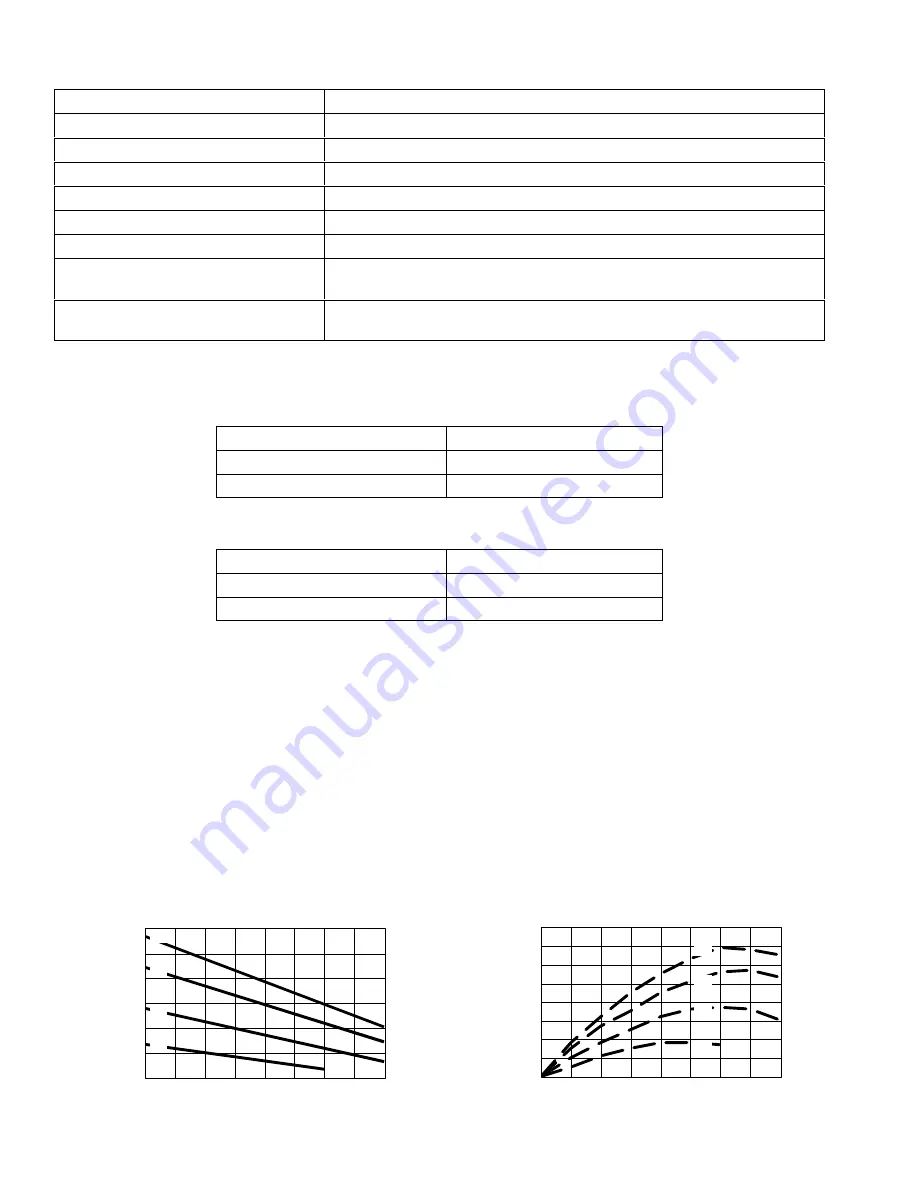

To find Fluid Outlet Pressure

(psi/MPa/bar) at a specific fluid flow

(lpm/gpm) and operating air pressure (psi/MPa/bar):

1.

Locate desired flow along bottom of chart.

2.

Follow vertical line up to intersection with selected fluid outlet

pressure curve (black). Follow left to scale to read fluid outlet

pressure.

To find Pump Air Consumption

(l/min or scfm) at a specific fluid flow

(lpm/gpm) and air pressure (psi/MPa/bar):

1.

Locate desired flow along bottom of chart.

2.

Read vertical line up to intersection with selected air consumption

curve (dashes). Follow left to scale to read air consumption.

A

115 psi (0.8 MPa, 8 bar) air pressure

B

90 psi (0.6 MPa, 6 bar) air pressure

C

60 psi (0.4 MPa, 4 bar) air pressure

D

30 psi (0.2 MPa, 2 bar) air pressure

Performance Chart

0

20

40

60

80

100

120

0

1

2

3

4

5

6

7

8

Fluid Outlet Pressure

24

47

71

psi

MPa, bar

cycles per minute

gpm

l/min

22.8

7.6 11.4

FLUID PRESSURE

0.8, 8.0

0.4, 4.0

A

B

C

Air Consumption

scfm

l

/

min

AIR CONSUMPTION

84

56

Test Fluid: No. 10 Weight Oil

0.14, 1.4

118

28

112

0.6, 6.0

0.3, 3.0

30.4

94

0.7, 7.0

141 165 188

3.8

15.2 19.0

26.6

D

140

168

196

224

PTFE

PTFE

PTFE