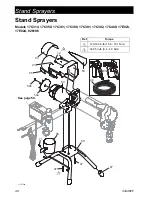

Hi-Boy Sprayers

334466F

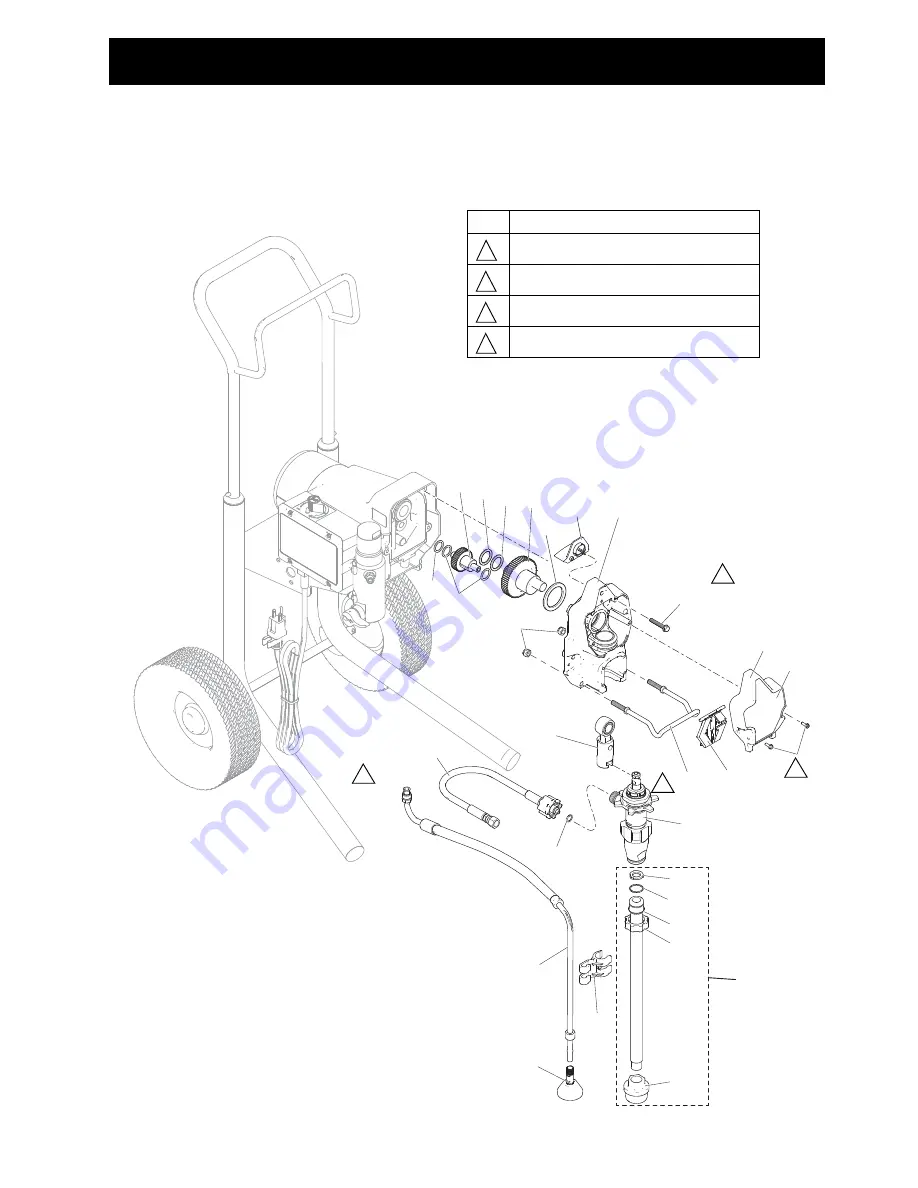

47

Models 17C317, 17C362, 17C408, 17E025, 17E026, 826198

40

44

42

26

28

29

27

47

43

41

132

45

22

52

12

70

91

55

39

136

137

60

57

14

84

96

62

ti24830a

25

117

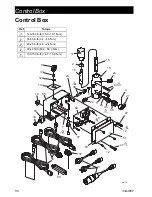

Ref.

Torque

140-160 in-lb (15.8 - 18.1 N•m)

30-35 in-lb (3.4 - 4.0 N•m)

Hammer tight

25-30 ft-lb (33.8 - 40.6 N•m)

1

2

3

4

4

3

1

2