Motor

WARNING

To reduce the risk of serious injury, follow the

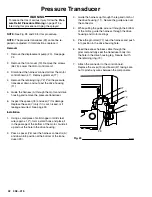

Pres-

sure Relief Procedure Warning

on page 21 be-

fore doing this procedure. Unplug the sprayer!

NOTE:

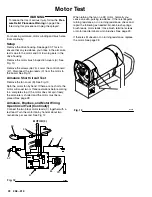

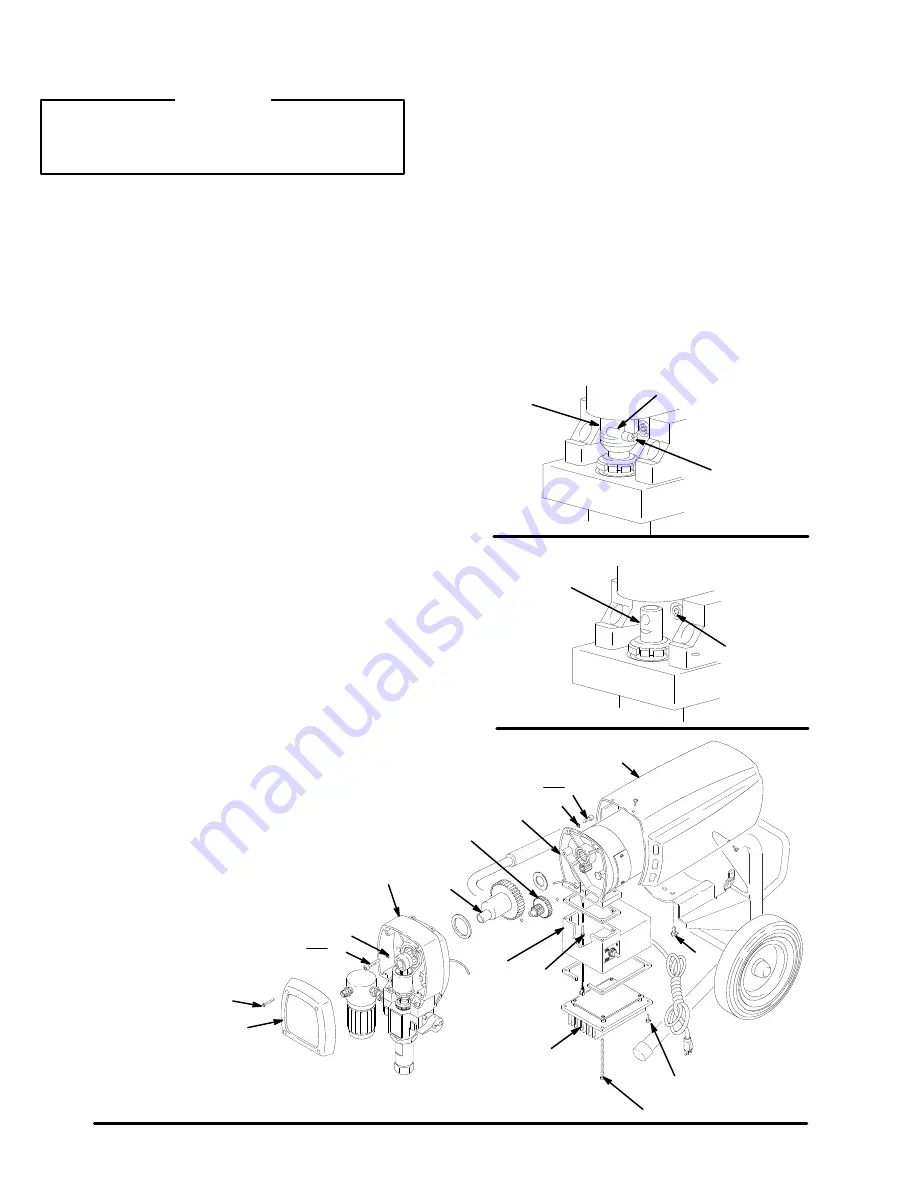

See Fig. 26 except where noted.

1. Relieve pressure.

2. Remove the motor shield (4).

3. Try to stop the pump with the piston rod (107) in its

lowest position. To lower the piston rod manually,

rotate the motor fan blades. Use a screwdriver to

push the retaining spring (18) up and push out the

pin (17). See Fig. 24.

4. Remove the shroud (4).

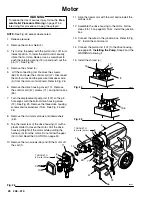

5. Lift the connecting rod. Remove the screws

(56,75) and lower the control card (47). Disconnect

the motor wires and the pressure transducer wire

(A) from the motor control board. Refer to Fig. 26.

6. Remove the drive housing cover (13). Remove

the control card (47), screws (71), and junction box

(59).

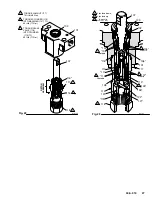

7. Turn the displacement pump rod (107) so the pin

hole aligns with the bottom drive housing screw

(19). See Fig. 25. Remove the three drive housing

screws and lockwashers (19,6). See Fig. 25 and

26

.

8. Remove the two motor screws and lockwashers

(5,6).

9. Tap the lower rear of the drive housing (11) with a

plastic mallet to loosen the motor. Pull the drive

housing straight off the motor while guiding the

harness (A) from the motor. Do not allow the gear

(16) to fall. Read the CAUTION on page 30.

10. Remove the two screws (46) and lift the motor off

the cart (1).

11. Align the new motor with the cart and reinstall the

screws (46).

12. Assemble the drive housing to the motor. Follow

steps 8 to 14 on page NO TAG. Install the junction

box.

13. Connect the wires in the junction box. Refer to Fig.

12. Install the control card.

14. Connect the piston rod (107) to the drive housing;

see page 24,

Installing the Pump

, Step 2 and the

WARNING following it.

15. Install the shroud (4).

17

18

15

Fig. 24

01068

107

19,6

Fig. 25

01074

19

6

13

34

59

56

12

16

11

4

5

6

46

TORQUE TO

80 in–lb (9 N.m)

TORQUE TO

80 in–lb (9 N.m)

Fig. 26

A

02994

75

47

71