Service

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection,

D

Follow the

Pressure Relief Procedure on page

6 when you stop dispensing, before servicing

the gun, and whenever you are instructed to

relieve the pressure.

D

After adjusting or servicing the gun, make sure

the fluid will not trigger on when the trigger safe-

ty is locked. If fluid does flow, the gun is not

assembled properly or the trigger safety is dam-

aged. Reassemble the gun or return it to your

nearest Graco distributor. Do not use the gun

until the problem is corrected.

D

When removing the gun from the hose, hold the

hex end of the fluid tube (19) securely to avoid

loosening the fluid tube from the gun body. Re-

fer to Fig. 6, page 13.

WARNING

SERVICE NOTES:

INJECTION HAZARD

To reduce the risk of a serious injury,

including fluid injection, if fluid continues

to flow after the trigger is released, ser-

vice the gun immediately as instructed below. Do

not use the gun until the problem is corrected.

WARNING

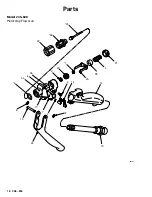

1. The numbers in parentheses in the text refer to

reference numbers in the drawings.

2. If the fluid continues to flow after the trigger is

released, the gun valve may need adjustment, be

obstructed or damaged, or the valve stem (24),

seat (26), or seal (3) may be worn or damaged.

See Fig. 4, page 11.

a. Adjust the valve or the spring tension as

instructed on page 9.

b. Replace the valve seal, stem, or seat as

instructed on page 10.

c. To inspect the valve for obstruction or damage,

disassemble the gun as instructed on page 11.

Clean and inspect the parts. Replace any worn

or damaged parts and reassemble the gun as

instructed on page 11.

3. Follow the torque, sealant and lubrication notes for

your gun model number.

4. The following repair kits are available:

Gun

Model

Repair

Kit

Description

235–627

235–658*

6.5

_

needle, seat, urethane

seal

235–875

R

seal, o-rings only

235–869

20

_

needle, seat, urethane

seal

237–596

7.5

_

carbide needle, seat, ure-

thane seal

235–628

235–829*

Carbide ball seat, urethane

seal

235–875

R

seal, o-rings only

237–607

237–596*

7.5

_

carbide needle, seat,

urethane seal

235–875

R

seal, o-rings only

235–869

20

_

SST needle, seat, ure-

thane seal

237–649

237–596*

7.5

_

carbide needle, seat,

urethane seal

* These are the standard Repair Kits for the gun

models. The other kits listed are optional.

NOTE: The fluid flow rates of guns using Repair Kits

235–658 and 237–596 are similar. Kit 235–869 will pro-

vide increased fluid flow. Kits 235–658 and 235–869

should not be used to dispense abrasive fluids.

PTFE

PTFE

PTFE

Summary of Contents for Ultra-lite 235627

Page 5: ... Notes ...

Page 21: ...308 253 21 Notes ...

Page 22: ... Notes ...

Page 23: ... Notes ...