12 308936

Gun Setup

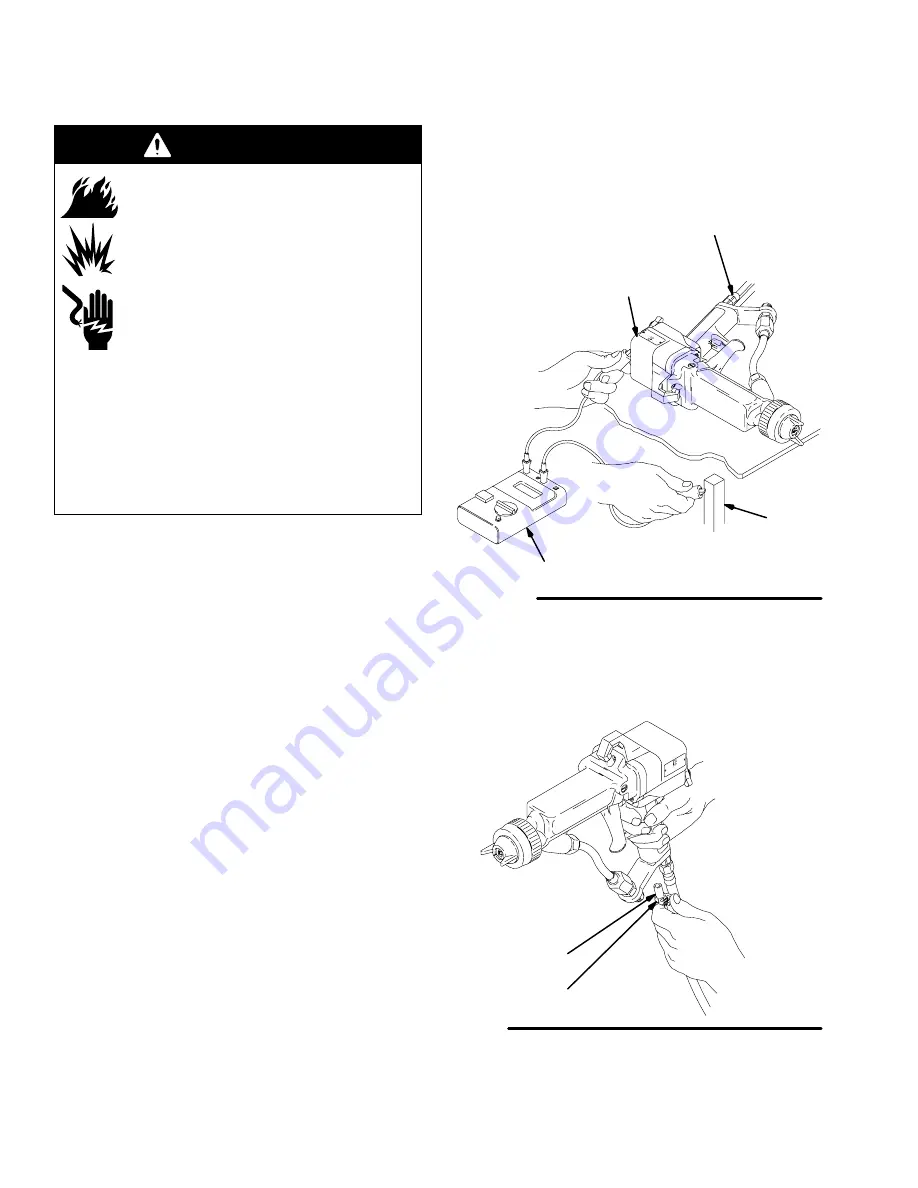

3. Check the gun’s electrical grounding.

WARNING

FIRE, EXPLOSION, AND

ELECTRIC SHOCK HAZARD

Megohmmeter P/N 218979 (E) is not

approved for use in a hazardous area.

To reduce the risk of sparking, do not

use the megohmmeter to check electri-

cal grounding unless:

The gun has been removed from the

hazardous area;

Or all spraying devices in the hazardous area

are turned off, ventilation fans in the hazardous

area are operating, and there are no flammable

vapors in the area (such as open solvent con-

tainers or fumes from spraying).

Failure to follow this warning could cause fire,

explosion, electric shock and result in serious injury

and property damage.

A.

Have a qualified electrician check the electrical

grounding continuity of the spray gun and air hose.

B.

Turn the ES ON-OFF Lever to OFF.

C.

Turn off the air and fluid supply to the gun. The

fluid hose must not have any fluid in it.

D.

Make sure the air hose (A) is connected and the

hose ground wire is connected to a true earth

ground.

E.

Measure the resistance between the

gun handle

(7) and a

true earth ground (D).

a.

If using a black or grey air hose,

use a me-

gohmmeter E) to measure the resistance. Use

an applied voltage of 500 minimum to 1000

volts maximum. The resistance should not

exceed 2 megohms.

b.

If using a red turbine air hose,

use an ohmme-

ter to measure the resistance. Resistance

should not exceed 100 ohms.

F.

If the resistance is greater than the maximum

reading specified above for your hose, check the

tightness of the ground connections and be sure

the air hose ground wire is connected to a true

earth ground. If the resistance is still too high, re-

place the air hose.

01946A

E

A

Fig. 3D–E

D

7

4. Connect the gun exhaust tube.

Press the exhaust tube (56) onto the barbed adapter

on the bottom of the gun handle. Secure the tube with

the clamp (57) provided.

Fig. 4

01992A

56

57

Summary of Contents for UNICARB

Page 40: ...40 308936 Notes ...