Component Identification

18

313873J

ADM Screen Components

See the ADM appendix sections beginning with

Appendix A - ADM Icons Overview

on page 57 for more informa-

tion.

F

IG

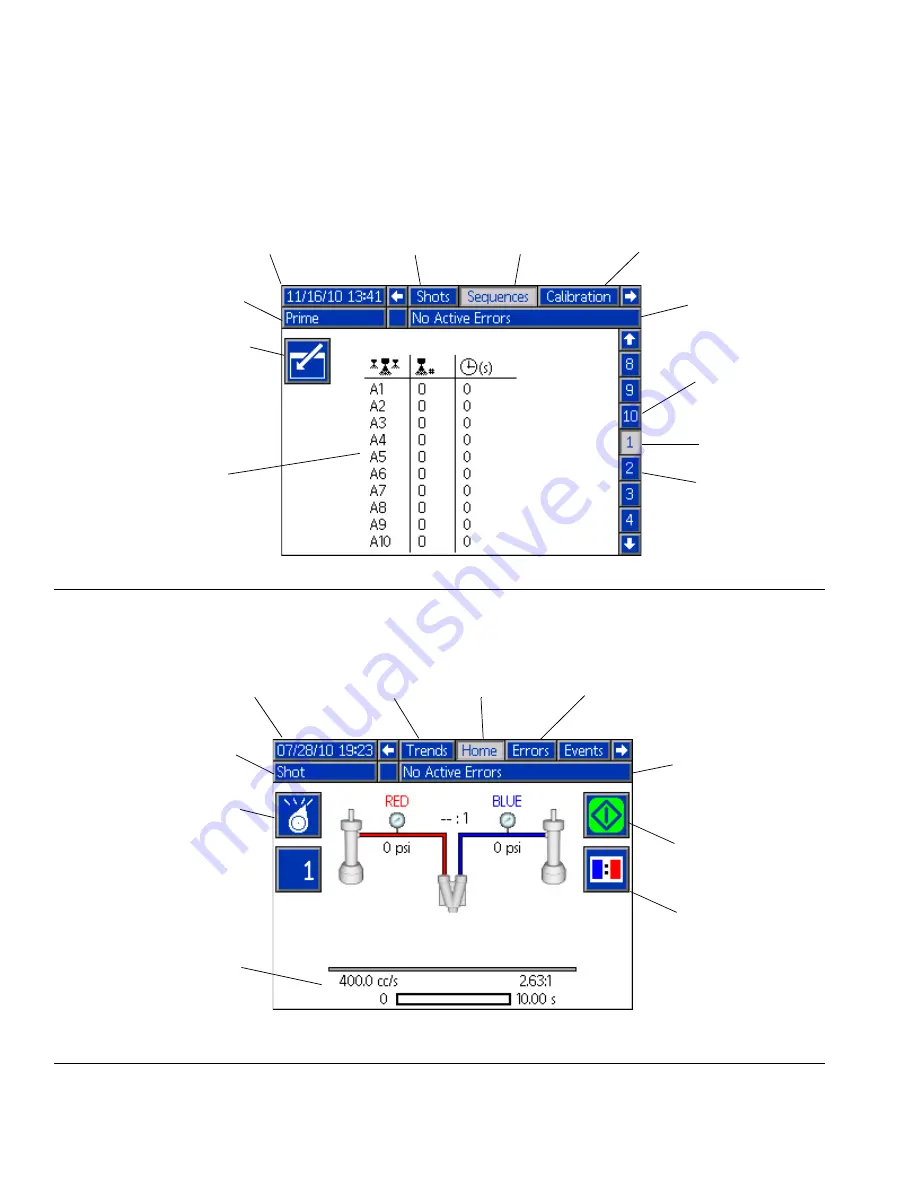

. 7: Main Display Components - Typical Setup Screen

F

IG

. 8: Main Display Components - Home Screen (Shot mode shown)

Current date and time

Current screen

Enter/Exit screen

Previous screen

Next screen

Settings Detail

Current

screen no.

Next

screen no.

Previous

screen no.

Operating Mode

Faults, Status

Current date and time

Current screen

Change Operating

Mode

Previous screen

Next screen

Dispense Details

Operating Mode

Faults, Status

Initiate Dispense

Initiate Ratio

Check Dispense