Air

Air

Air Valve

Valve

Valve Repair

Repair

Repair

1.

Follow the steps in

Prepare the Gun for Service, page 58

2.

Follow the steps in

.

3.

Remove the screws (13) and trigger (12).

4.

Remove the ES On-Off Valve. See

and Fluid Adjustment Valve Repair, page 71

.

5.

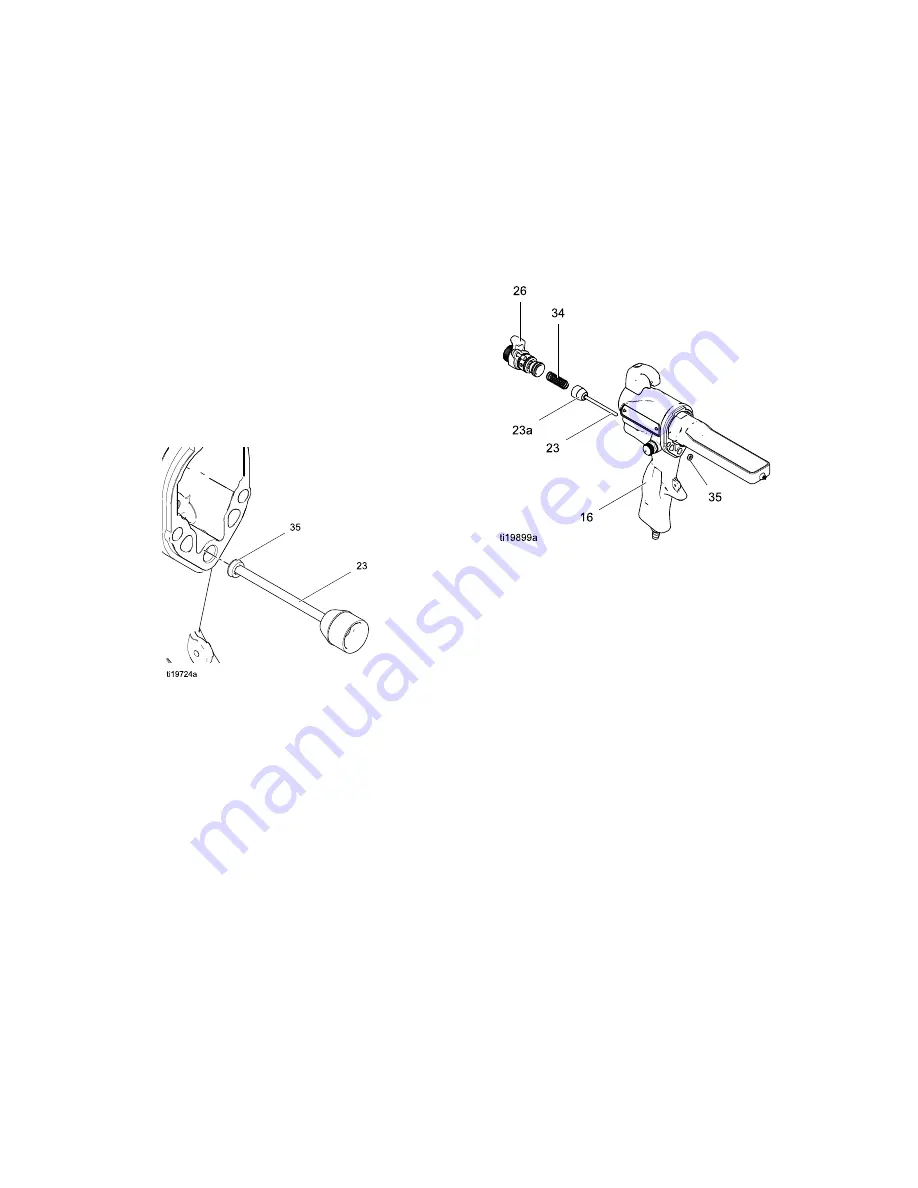

Remove the spring (34).

6.

Push on the front of the air valve shaft to force it

out the back of the handle. Inspect the rubber

seal (23a*) and replace if damaged.

7.

Inspect the u-cup (35). Do not remove the u-cup

unless damaged. If removed, install the new one

with its lips facing into the gun handle (16). Place

the u-cup on the shaft of the air valve to help seat

it in the gun handle.

Figure 53 Install U-Cup

8.

Install the air valve (23) and spring (34) into the

gun handle (16).

9.

Install the ES On-Off Valve. See

Fluid Adjustment Valve Repair, page 71

.

10. Install the trigger (12) and screws (13).

11. Follow the steps in

.

Figure 54 Air Valve

72

3A2496H