13

307–959

SPRAYER REPAIR

WARNING

Always follow the

Pressure Relief Procedure

Warning

on page 8 before doing any repair.

Motor Repair

1. Remove the following: bottom cover (42), screws

(28), handle (32), shield (79), front cover (23). Refer

to the Parts Drawing.

2. Disconnect the motor leads from the positive and

negative rectifier terminals. See Fig 11.

3. Remove the motor screws (20) and

lockwashers

(21). Lift the motor (30) slightly. Hold the connecting

rod while pulling the motor away from the housing

(22). See Fig 10.

4. Inspect the bearing (18b) in the connecting rod (18a).

If it is worn or any rollers are broken, replace the

bearing and rod assembly (18). See Fig 10.

5. Use your fingers to pack high–quality bearing grease

thoroughly between the bearing rollers. See Fig 10.

6. Guide the motor leads through the grommet (69).

Align the motor with the pins in the connecting rod

housing (22). Guide the motor eccentric through the

connecting rod bearing (18b). Spin the motor shaft to

be sure it moves freely. See Fig 10.

7. Loosely install the lockwashers (21) and screws (20).

Spin the motor shaft again. Alternately tighten the

screws. Spin the motor shaft again.

Spin the motor shaft while assembling the pump to

ensure that parts are properly aligned. If they are

not, and the pump is started, serious damage could

result to the motor, bearing, and connecting rod. If

there is binding or resistance, disassemble the

parts. Check the spin often until you determine the

cause of the binding.

CAUTION

8. Connect the red motor lead to the positive (+) termi-

nal and the black motor lead to the negative (–) termi-

nal of the rectifier (39). See Fig 11.

9. Reinstall all parts.

Fig 11

34

37 38

65

33 25

82,81,80

PRESSURE

SWITCH (2)

LEADS

JUMPER WIRE

GREEN WIRE

MOTOR

LEADS

WHITE

OUT

IN

RED

39

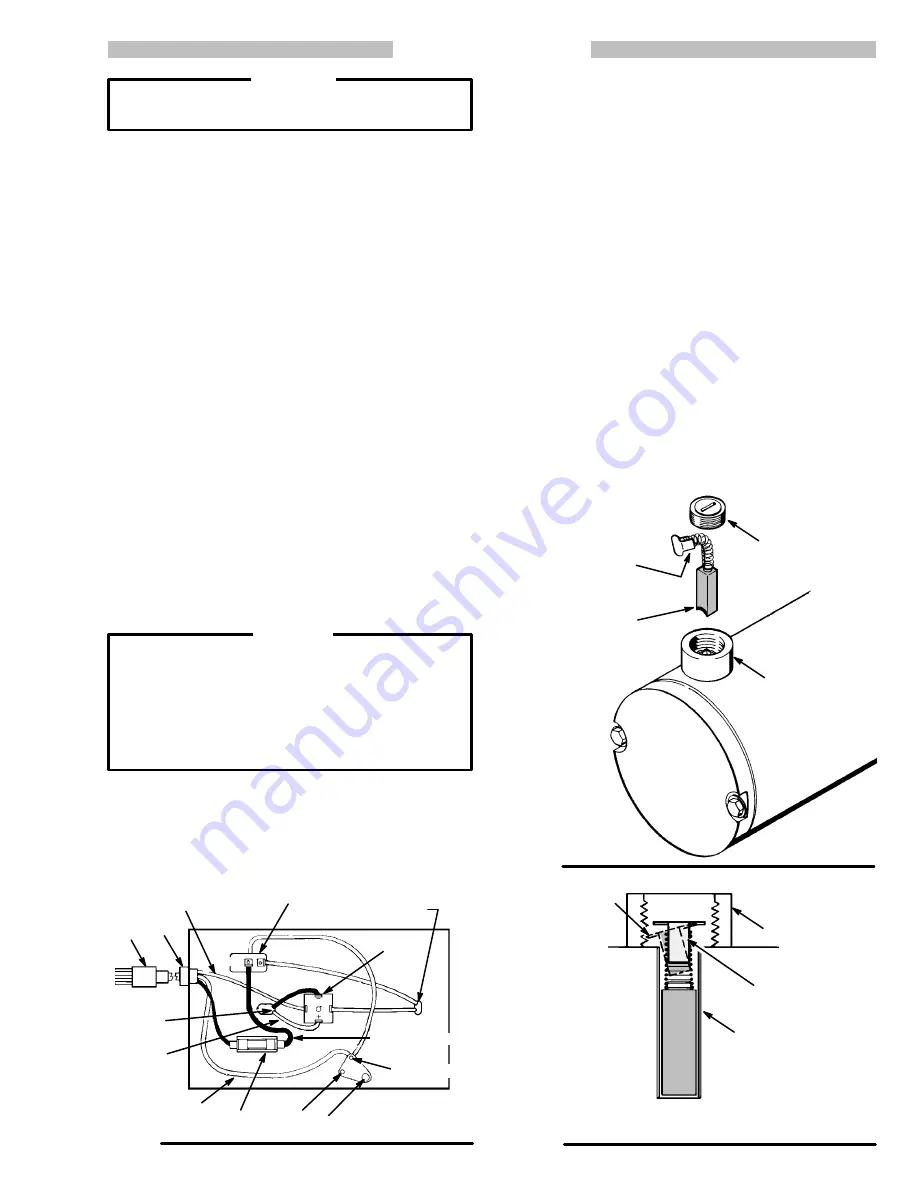

Motor Brush

1. Remove the bottom cover (42), screws (28), handle

(32) and shield (79). Refer to the Parts Drawing.

2. Remove the plug from each side of the motor and re-

move the brushes.

3. Install the new brush so its curve aligns with the

curve of the motor. See Fig 12.

4. Carefully push the copper contact into the brush

housing so its side tabs fit inside the holder. Tilt the

top of the contact so an edge of it catches in one of

the thread grooves. This holds the brush in place

temporarily. See Fig 13.

NOTE:

If necessary, start one tab into the holder , and

then use a small screwdriver to gently guide the

other tab into the holder.

5. Install the plug, applying even pressure so the brush

stays in place. If the plug does not turn in easily, re-

move it. Forcing the plug will damage the contact.

6. Repeat for the other side.

7. Reinstall all parts.

Fig 12

Fig 13

PLUG

Note curve of

brush. install curve

so it is parallel

with the curve of

the motor.

TABS OF

COPPER

CONTACT

BRUSH HOUSING

BRUSH HOUSING

Tabs of copper

contact fit squarely

in brush holder

Side view of brush installation does

not show curve of motor or brush

Tilt copper

contact so it is

held in place by

thread grooves in

brush housing.

BRUSH HOLDER