Empty and Flush Entire System (new system or end of job)

3A0420V

31

Empty and Flush Entire System

(new system or end of job)

NOTE:

•

If the system includes heaters and heated hose,

turn them off and allow to cool before flushing.

Do not turn on the heaters until the fluid lines

are clear of solvent.

•

Cover fluid containers and use the lowest possi-

ble pressure when flushing to avoid splashing.

•

Before color change or shutdown for storage,

circulate the solvent at a higher flow rate and for

a longer time. Change the solvent when it gets

dirty.

•

To only flush the fluid manifold, see Flush Mix

Manifold, Hose, and Spray Gun, page 30.

•

If the machine is inoperable, use drain plugs on

the pump inlet fittings.

Guidelines

Flush new systems if the coating materials will be con-

taminated by mineral oil.

Flushing will help prevent materials from settling or gell-

ing in the pumps, lines, and valves. Flush the system

when any of the following situations occur.

•

anytime the system will not be used for more

than one week (depending on materials used)

•

if the materials used have fillers that will settle

•

if using materials that are moisture sensitive

•

before servicing

•

if the machine is going into storage, replace the

flush solvent with light oil. Never leave the

equipment empty of any fluid.

Procedure

1. Follow

, page 25 and

Mix Manifold, Hose, and Spray Gun

, page 30, as

required.

2. Engage the trigger lock.

3.

XP Systems:

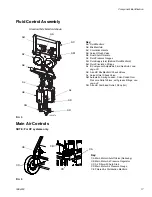

Turn the main pump air regulator

(CB) fully counter-clockwise to shut off.

XP-h Systems:

Set pump valve on.

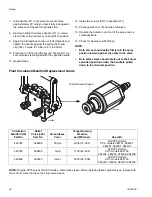

4. Move the recirculation lines (U) to separate fluid

containers to pump remaining fluid out of the sys-

tem.

5. Open the circulation handle (AC). See F

. 3 on

page 17.

6. Increase the main pump air regulator (CB) pressure

to 20 psi (138 kPa, 1.38 bar).

TI1949a

CB

r_571100_3A0420A_11a-1

ti7108a

U

Summary of Contents for XP-h

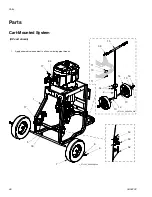

Page 45: ...Repair 3A0420V 45 ...

Page 69: ...Dimensions 3A0420V 69 ...