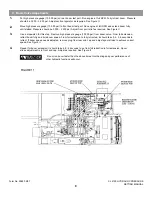

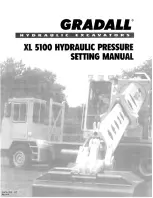

Put low pressure gauge (1,000 psi) on test port of pump supply line to bucket, hoist and tilt valve bank (large

valve bank). With engine running, gauge hose can be installed and then tighten down after engine starts. (Will

prevent spike damage to gauge). See Figure 7.

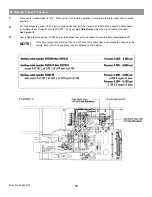

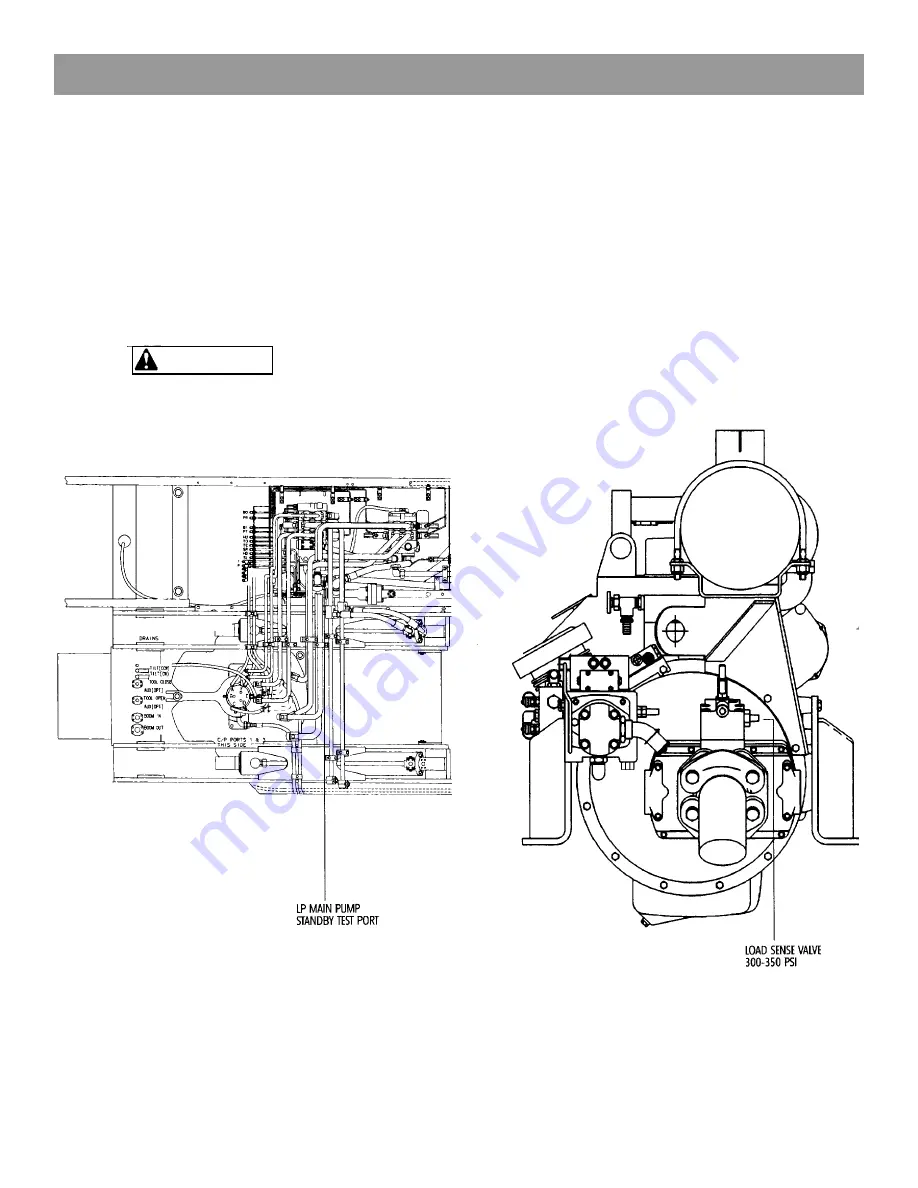

Leave right hand armrest up, run engine at full RPM. Pressure should read 300 - 350 psi. Adjust as required at

load sense valve on main pump (load sense valve is located at control block on main pump, facing the reservoir).

See Figure 8.

CAUTION

Do not operate any controls during this step. It will affect the reading and destroy the gauge.

FIGURE 7

Form No. 29621 2/97

FIGURE 8

6

VI. Main Pump Standby Pressure

1.

2.

Summary of Contents for XL4000

Page 2: ......

Page 73: ......

Page 76: ... 5MP ...

Page 145: ......

Page 146: ......

Page 160: ......

Page 161: ......

Page 162: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 207: ......

Page 208: ......

Page 210: ...500P ...

Page 229: ......

Page 230: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 265: ......

Page 266: ......

Page 267: ......

Page 268: ......

Page 280: ......

Page 281: ......

Page 282: ......

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......