V

V

V

V

V..... Swing Cir

Swing Cir

Swing Cir

Swing Cir

Swing Circuit Pr

cuit Pr

cuit Pr

cuit Pr

cuit Pressur

essur

essur

essur

essure

e

e

e

e Adjustments

Adjustments

Adjustments

Adjustments

Adjustments

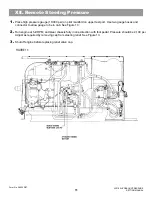

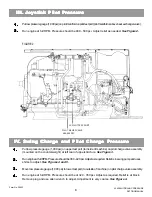

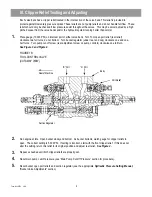

Assemble two GRADALL gauge hoses from test kit together with connector. Route across machine so that gauge

is in cab and hose will reach swing pump test ports. Carefully bleed hose into a bucket to get air out

of gauge hose.

Put high pressure gauge (10,000 psi) on inside test port on top of swing pump. Place boom firmly on ground, run

engine at full RPM and stall the swing to the right. Pressure should be 5,450 - 5,750 psi.

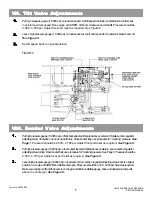

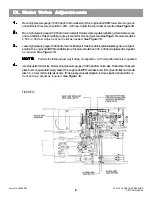

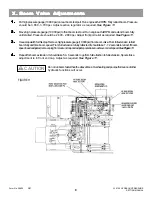

See Figure 6.

Adjust as required. Swing torque adjustment screw is at front center of torque control valve.

See Figure 6.

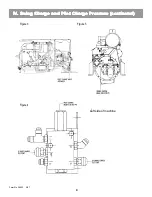

Put high pressure gauge (10,000 psi) on outside test port on top of swing pump. Place boom firmly on ground,

run engine at full RPM and stall the swing to the left. Pressure should be the same as the previous test within 200 psi.

If not, refer to the supplemental pressures manual (Form No. 29416) under swing pump begin point

adjustment.

Leave high pressure gauge (10,000 psi) on outside test port to test swing cushioning. Check nominal cushioning

setting at brake valve adjustment screw (located behind torque valve on swing pump). From the face of the valve,

the screw should extend out 12mm.

See Figure 6.

Lift boom off ground fully extend boom and swing machine to the right one complete revolution. The pressure will

rise when starting to swing, then will level off around 800 psi. Let off joystick and observe the pressure. Initially, the

pressure may rise to 4,000 - 5,000 psi, then level off to 3,300 - 3,500 psi. This is the correct setting. As the swing

coasts to a stop, the pressure will drop off further. Adjust as required.

See Figure 6.

NOTE!

With the boom fully retracted, the pressure should be 3,100 psi.

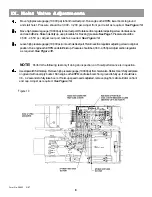

FIGURE 6

Form No. 29623

XL 5200 HYDRAULIC PRESSURE

SETTING MANUAL

5

1.

1.

1.

1.

1.

2.

2.

2.

2.

2.

3.

3.

3.

3.

3.

4.

4.

4.

4.

4.

5.

5.

5.

5.

5.

6.

6.

6.

6.

6.

Summary of Contents for XL4000

Page 2: ......

Page 73: ......

Page 76: ... 5MP ...

Page 145: ......

Page 146: ......

Page 160: ......

Page 161: ......

Page 162: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 207: ......

Page 208: ......

Page 210: ...500P ...

Page 229: ......

Page 230: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 265: ......

Page 266: ......

Page 267: ......

Page 268: ......

Page 280: ......

Page 281: ......

Page 282: ......

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......