II. Hydraulic System - General

Hydraulic System:

The XL 4200 and XL 5200 Hydraulic System is designed for efficient operation with a minimum amount of wear to

related system components. Air from an electric compressor and from the engine intake manifold pressurizes the

hydraulic system to 6-8 PSI. A 120 PSI backpressure valve is located in the main control valve banks return line.

These features ensure fluid is always present to components when required.

DO NOT OPEN

the hydraulic reservoir

without relieving air pressure. Serious injury could result from being sprayed with hot hydraulic fluid. Hydraulic fluid

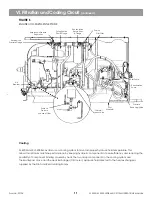

temperature is controlled by a cooler circuit which maintains the fluid temperature approximately 100° above

ambient temperature. Individual hydraulic components and circuitry will be explained in this Manual.

The primary circuits of the GRADALL XL Series Crawler -Mounted Excavator are as follows:

Main pump: Work circuits whose fluid is supplied by the main hydraulic pumps

Pilot Pump: Control circuits whose fluid is supplied by the pilot pump

Recirculating Pump: Cooling circuit directing a constant flow of fluid through the cooler

Swing Pump: Closed loop circuit separate from the main pump circuit

Hydraulic fluid:

Use only specified hydraulic fluid. Use of fluids other than those which meet specifications will

seriously damage the hydraulic components, resulting in expensive failure or machine

downtime. Approved fluids are:

Hydraulic Oil: M

bilfluid

®

424

or Citgo Tractor Hyd. Fluid #33310.

Fire-Resistant Fluid:

Quaker Chemical Quintolubric 822-300.

Do Not

use any other fluid

without first receiving

approval from your GRADALL Distributor or the GRADALL factory. Fluid specifications are listed in the lubrication chart

on your machine and the decal on the fluid reservoir of the upperstructure.

Add additional fluid through the main reservoir return filter when topping off the system. If the reservoir has been

drained, follow START-UP PROCEDURE.

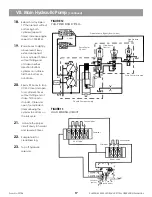

See Section V11, Main Hydraulic Pump.

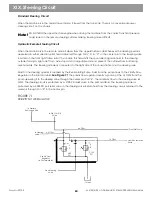

Hydraulic System logic is determined by the following: Load Sense Control which regulates standby pressure. High

Pressure Cutoff which senses pressure above 500 PSI then reduces pressure by destroking the pump. Horsepower

Control which does not let the engine draw down below 1900 RPM when all circuits are activated at the same time.

If repairs or adjustments to the hydraulic system become necessary, we recommend you contact GRADALL distributor

to have this work done by a qualified GRADALL technician.

See Appendix B & Appendix C for circuit operating times.

XL 4200/XL 5200 HYDRAULIC SYTEM OPERATIONS MANUAL

Form No. 29704

3

Summary of Contents for XL4000

Page 2: ......

Page 73: ......

Page 76: ... 5MP ...

Page 145: ......

Page 146: ......

Page 160: ......

Page 161: ......

Page 162: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 207: ......

Page 208: ......

Page 210: ...500P ...

Page 229: ......

Page 230: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 265: ......

Page 266: ......

Page 267: ......

Page 268: ......

Page 280: ......

Page 281: ......

Page 282: ......

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......