IX. Gear Pump

XL 4200/XL 5200 HYDRAULIC SYTEM OPERATIONS MANUAL

Form No. 29704

21

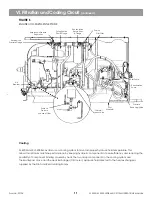

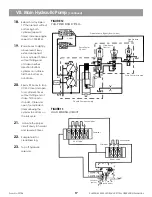

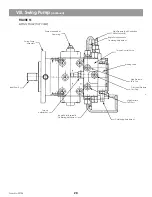

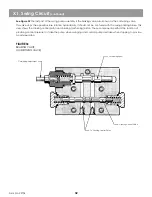

This small tandem gear pump is mounted at the rear of the swing pump. It is driven by the thru-drive from

the swing pump. The input shaft drives the gear of both pump sections.

See Figure 15, Figure 17, Figure 18 and

Figure 19.

Fluid is supplied to both pump sections via a common feed tube from the reservoir using a separate

outlet in each section. The front outlet is from the 14 GPM section that supplies fluid to the heat exchanger (oil

cooler) and return filter. The rear outlet is from the 6.6 GPM section that supplies fluid the pilot system.

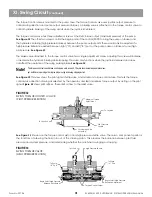

No adjustments are provided for the gear pumps. If problems are suspected, they can be checked with a flow

meter

and repaired, or replaced if flow is 10% below rated flow at the working pressure cited in each section.

FIGURE 17

FIGURE 18

Pilot

Pump

Recirculation

Pump

Recirculation

Pump

Pilot Pump

Summary of Contents for XL4000

Page 2: ......

Page 73: ......

Page 76: ... 5MP ...

Page 145: ......

Page 146: ......

Page 160: ......

Page 161: ......

Page 162: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 207: ......

Page 208: ......

Page 210: ...500P ...

Page 229: ......

Page 230: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 265: ......

Page 266: ......

Page 267: ......

Page 268: ......

Page 280: ......

Page 281: ......

Page 282: ......

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......