Form No. 29704

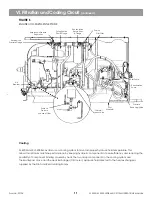

X. Pilot Circuit

(continued)

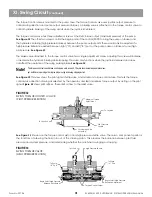

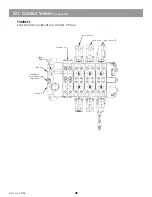

Pilot Circuit Solenoid Cut-Off Valve

Function:

Activated:

Location:

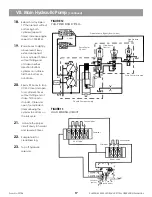

JOYSTICKS

GRADALL uses two types of Pilot Controllers. Two joysticks are used for the boom controls and two foot pedals are

used for the travel and steer functions (one each). Hydraulic fluid to the pressure ports comes from a 6.6 GPM pilot

pump. The pilot pump is in the rear section of the tandem gear pump behind the swing pump. Pilot pressure going

to the P port on the joysticks should be 480 PSI.

The two joysticks used for the boom functions are identical. They have six ports in the bottom of the housing and

are marked, P for pressure in, T for dump, and 1-4 for the ports going to the end caps of their respective main

control valve bodies. The joysticks can withstand 725 PSI and are rated for 4.8 GPM. The seals in the joysticks are

Buna-N.

See Figure 22, Figure 23 and Figure 24

All the spring packs are identical. When the hand lever is moved approximately four degrees, approximately 75 PSI

will be directed to the valve end caps. As the hand lever is progressively moved, the pressure should rise in a linear

fashion. At 19° and opproximatey 400 PSI the forced opening will be reached. The pressure will rise rapidly to pilot

pressure and metering capability will be greatly reduced. In the Neutral position, the operating lever is held at zero

degrees by the four return springs. When the lever is operated, the plunger is pushed against the return spring by

the cam plate. At the same time, the regulating spool is pushed through the regulating springs. This modulates

supply pressure from the P port to one or more of the four working ports, on to the valve end caps then to the

swing pump. It is important to remember that joysticks do not regulate flow, they regulate pressure.

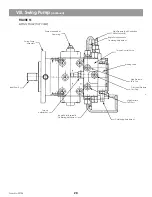

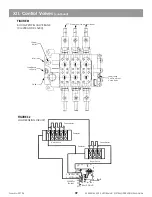

FOOT PEDALS

GRADALL uses the same pedal valves for travel in the crawlers as well as the truck mounts. They are basically the

same as the joysticks, but only hove two pressure reducing valves instead of four. They ore protected from the

elements by rubber sleeves, stainless steel push rods and brass bushings. At rest, the foot pedal is held in its

Neutral position by two return springs. The two working ports are connected to the tank port. When the foot pedal

is depressed, the push rod is pressed against the large return spring as well as the inner control spring. The control

spring initially moves the control spool downward and closes the connection between the relevant working port and

the tank port. At the some time, the relevant working port is now connected to the pressure port that was dead

headed. Due to the interaction between the control spool and the control spring, the pressure in the relevant working

port is proportional to the stroke of the push rod and hence to the position of the pedal.

Stop pilot circuit fluid from reaching controls. When energized, all hydraulic circuits ore neutralized,

and will not engage·

By a switch connected to the operators sect right armrest. Whenever the armrest is raised the switch is

engaged and all circuit hydraulics are cut off. Pilot fluid returns to the reservoir.

Solenoid valve in main control valve compartment. Switch in electric circuit under right armrest of the

operators seat in upperstructure cab.

24

l

l

l

Summary of Contents for XL4000

Page 2: ......

Page 73: ......

Page 76: ... 5MP ...

Page 145: ......

Page 146: ......

Page 160: ......

Page 161: ......

Page 162: ......

Page 175: ......

Page 176: ......

Page 177: ......

Page 178: ......

Page 192: ......

Page 193: ......

Page 194: ......

Page 207: ......

Page 208: ......

Page 210: ...500P ...

Page 229: ......

Page 230: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 265: ......

Page 266: ......

Page 267: ......

Page 268: ......

Page 280: ......

Page 281: ......

Page 282: ......

Page 297: ......

Page 298: ......

Page 299: ......

Page 300: ......

Page 301: ......

Page 302: ......

Page 303: ......

Page 304: ......