Cleaning

41

IMPORTANT!

Do not lay removed parts on top of each other as this may damage parts.

Only clean the beater and the chain frame with the brush provided. Do not

press too hard.

4.1.1 Disassembly of the Removable Parts

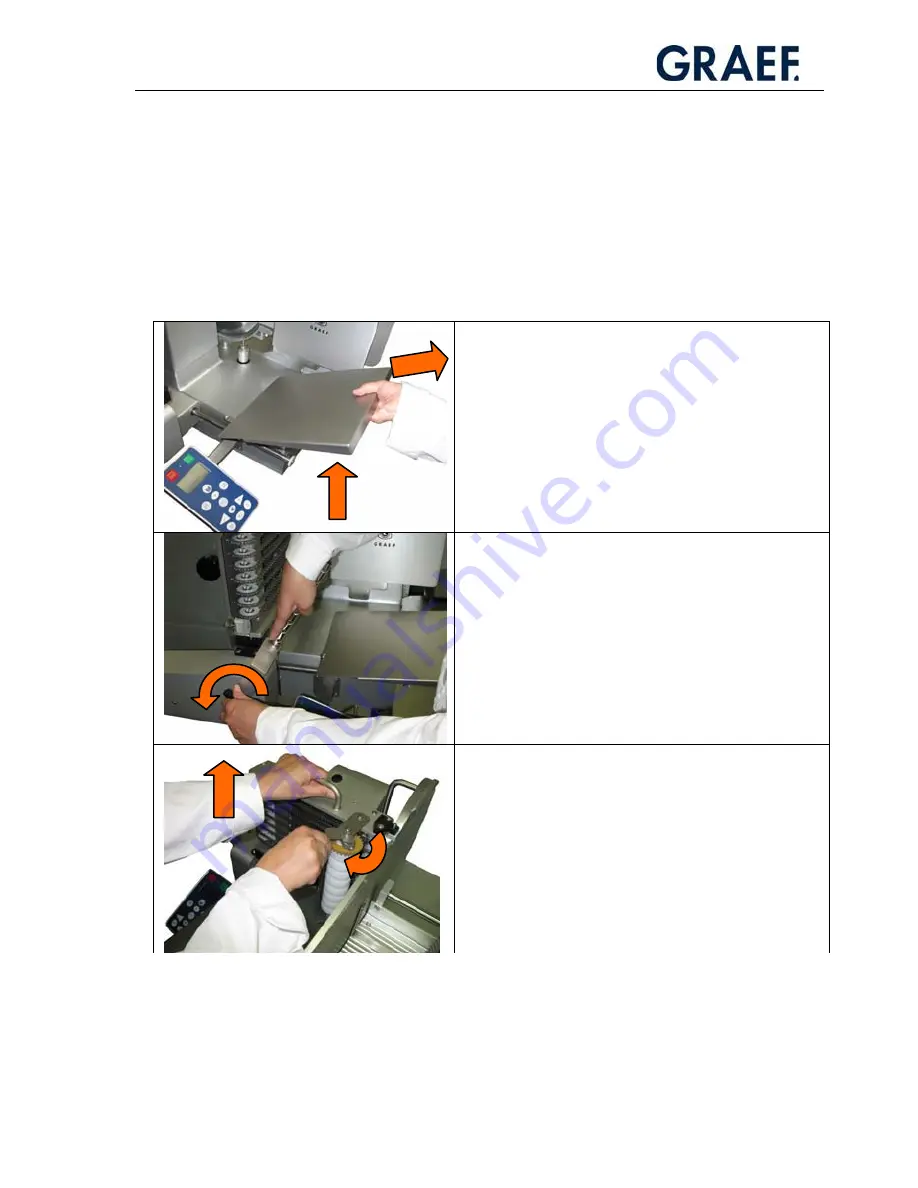

Tray:

x

Lift the tray as shown in the picture.

x

Move the tray towards the operator and remove it

from the machine.

Placing arm:

x

Remove the star grip while fixing the placing arm to

the beater rod.

x

Take the placing arm from the machine.

Chain frame:

x

Swing the pressing roller away from the limit stop

with your right hand.

x

Pull the chain frame upwards by the handle with your

left hand and remove it from the machine.

!

1

2

2

1