8

.

Fault messages and rectification

30 / 40

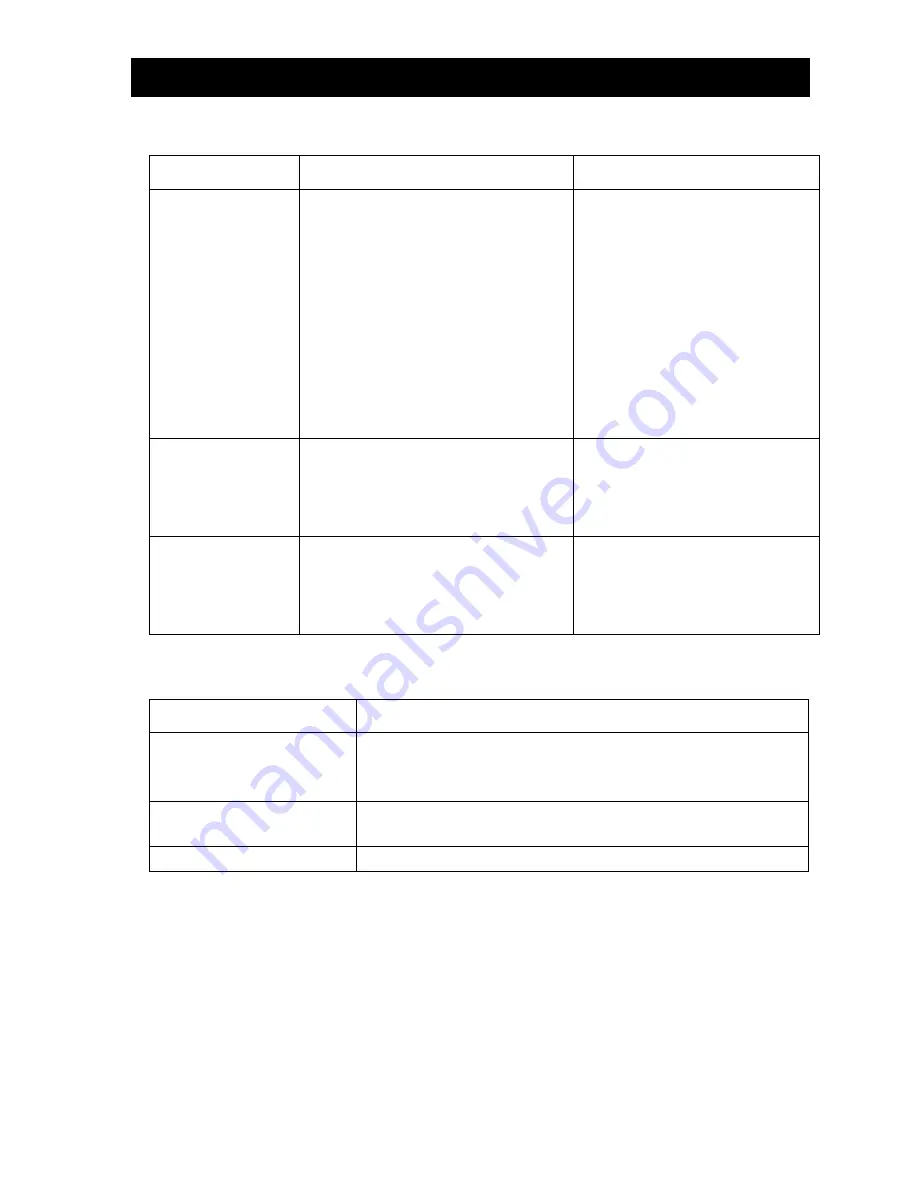

Unusual water levels - troubleshooting

8.2

Observation

Possible cause

Corrective action

The water level in the

aeration tank is unu-

sually high.

Plant is running in holiday mode.

Plant is constantly running in cycle

pause.

Control settings are incorrect.

The outflow lifter is congested.

The air hose to the outflow lifter is

leaking.

Flooding in the receiving water

course doesn't allow water to drain

from plant.

Controller is defective.

Ending of holiday mode

Have the controller settings

checked by service technician

Have SBR reactor pumped out

and clean lifter

Have SBR reactor pumped out

and seal hose connections

Wait until flooding subsides,

Contact maintenance company

The plant emits

odours, the treated

wastewater is cloudy

or discoloured

Too little air is supplied to the plant

One-sided aeration due to defective

membrane unit

Have aeration time increased by

service company

Verify aeration diagram, contact

maintenance company

Aeration diagram is

one-sided and large,

isolated bubbles are

rising

Membrane unit defective

Aerator unit is leaking

Aerator unit is not positioned correctly

on the bottom

Contact maintenance company

Contact maintenance company

Possible faults at the air distributor (valve block)

8.3

Observation

Possible cause

Anchor does not pick up.

Supply voltage is interrupted or insufficient.

Motor defective!

Anchor blocked in polluted tube space.

Valve does not close.

Anchor blocked!

No power supply

Valve does not open.

Nominal voltage is not present

Status: 12 / 2017

Specifications subject to change without notice!

Summary of Contents for one2clean+ XXL

Page 39: ...13 Notes 39 40 13 Notes ...