12

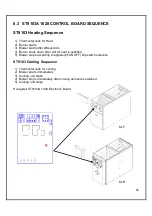

5.2 SET BURNER FOR EFFICIENT OPERATION

BURNER SETTING

Use burner settings in the table on page 14 (KLR) and 15 (KLF) or

operating decal as a guide to set burner, particularly for nozzle

changes. Those settings are only starting points for the

adjustments and are not meant as final settings.

On Beckett AFG burner, make sure the correct retention head and

static disk are installed on the burner for the desired firing rate. The

head is held in place by two screws at the end of the burner blast tube.

From the burner technical information table on page 14 (KLR) and 15

(KLF), the head is always after the AFG designation and the static disk

after the head. For example, the AFG L2 3’’ 3/8 means an AFG

chassis burner with a L2 head and a static disk of 3’’ 3/8.

PUMP PRESSURE

Refer to the table on page 14 (KLR) and 15 (KLF) or operating decal.

AIR SETTING

Use air settings on page 14 (KLR) and 15 (KLF) as a guide to set air

adjustment. Those settings are only starting points for the

adjustments and are not meant as final settings.

DRAFT REGULATOR The draft regulator should be installed at least 3 flue pipe diameter

from breeching or elbow of the furnace.

SAMPLING HOLE

On smoke/vent pipe, drill a 3/8” round opening. The hole should be at

least 2 flue pipe diameter from breeching or elbow of the furnace.

FRONT FLUE FURNACE ILLUSTRATION

Summary of Contents for KLF-200

Page 7: ...6 KLR 200 DIMENSIONS Dimensions are in inches KLF 200 DIMENSIONS Dimensions are in inches...

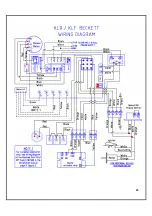

Page 25: ...24 8 0 ELECTRICAL WIRING DIAGRAMS...

Page 26: ...25...

Page 27: ...26 GeniSys control schematic with the ST9103 Board...

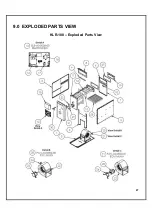

Page 28: ...27 9 0 EXPLODED PARTS VIEW KLR 100 Exploded Parts View...

Page 30: ...29 KLR 200 Exploded Parts View...

Page 32: ...31 KLF 200 Exploded Parts View...