12

GrandCanyonGasLogs.com

customerservice@grandcanyongaslogs.com

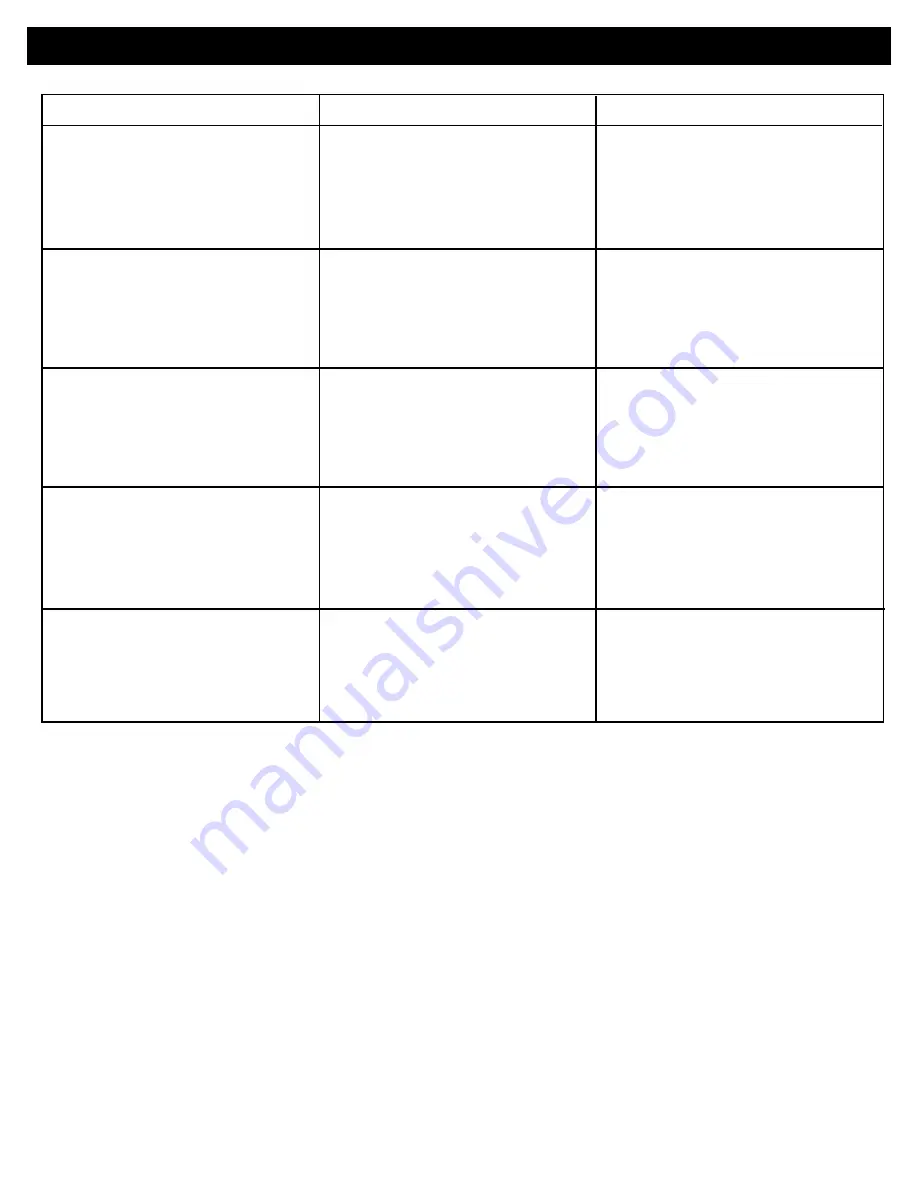

TROUBLESHOOTING

PROBLEM

CAUSE

SOLUTION

1. Pilot will not light

a Obstruction in pilot gas supply or

pilot gas-supply line is kinked

b. Inadequate gas pressure

c. Air in line

a. Clear out obstruction.

Replace pilot gas-supply line if

kinked

b. Have gas pressure checked by

installer or gas supplier

c. Air should clear; attempt to relight

2. Pilot will not stay lit

a. Loose wires

b. Low gas pressure

c. Faulty thermopile

d. Safety magnet wire not connected

on TH TP terminal

a. Check all wires are securely in

place

b. Check gas pressure

c. Check MV voltage

d. Connect safety magnet wire to

TH TP terminal

3. Pilot lights, but main

burner will not

a. Wire leads are not connected to

proper valve terminals

b. Batteries too low for voltage

output

c. Defective valve

a. Make sure all wire leads are tight

and attached to proper terminals

(see wiring diagram section pg 4)

b. Replace with new ones

c. Replace valve

4. Burner system not burning

properly

a. Low flame/uneven flame

a. Check for low gas pressure;

should have operating pressures

of 5" w.c. for natural gas, 11" w.c.

for propane at manifold

5. Burner system shuts

down during operation

a. Glass doors closed, causing

excessive heat buildup

b. Pilot electrode not properly set to

pilot location

c. Heat shield not in place

a. Open glass doors

b. See INSTALL (page 8)

c. Place heat shield over valve

Periodically inspect the pilot assembly and valve controls and maintain them free of obstruction or debris. If the pilot flame is

not blue with possibly yellow tips and does not impinge on the electrodes or if the pilot does not stay lit, contact a qualified

professional service technician to service the pilot system.