INSTALLATION INSTRUCTIONS

R

−

410A Split System Heat Pump

428 01 5301 05

13

Specifications subject to change without notice.

11. If outdoor air temperature or pressure at suction

valve changes, charge to new suction line

temperature indicated on chart.

12. Optimum performance will be achieved when

the operating charge produces 5

_

to 6

_

F

suction superheat at suction service valve

with 82

_

F (28

_

C) outdoor ambient and 80

_

F

(27

_

C) dry bulb (67

_

F / 19

_

C) wet bulb) indoor

temperature (DOE “B” test conditions) at rated

airflow.

C. HEATING MODE

To check system operation during heating cycle, refer to

the Tech Label on outdoor unit. This chart indicates

whether a correct relationship exists between system

operating pressure and air temperature entering indoor

and outdoor units. If pressure and temperature do not

match on chart, system refrigerant charge may not be

correct. Do not use chart to adjust refrigerant charge.

NOTE:

When charging is necessary during heating

season, charge must be weighed in accordance with unit

rating plate

0.6 ounces per foot of

a

inch liquid line above

or below 15 feet respectively (

17g per 305mm of 10mm

liquid line above or below 4.6m respectively).

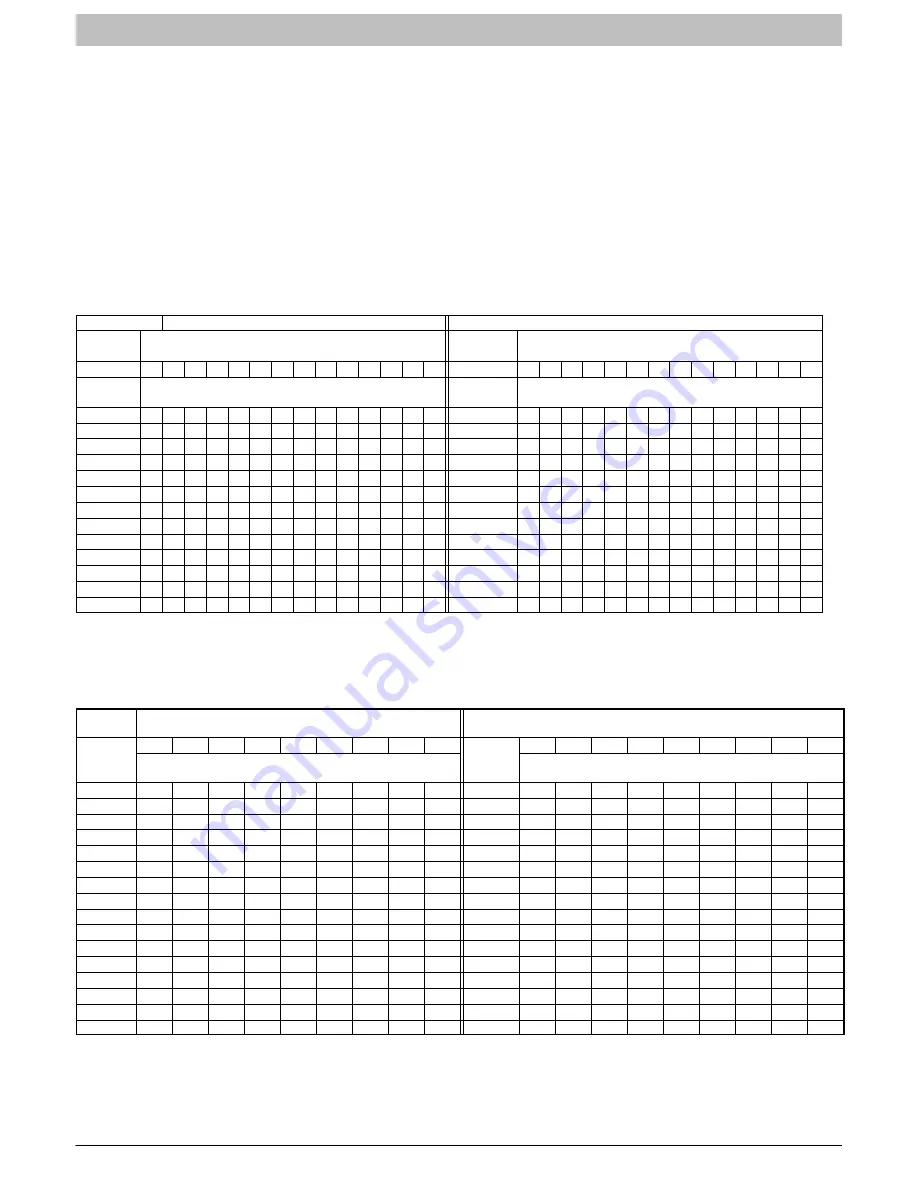

Figure 13

SUPERHEAT CHARGING TABLE ˚F

SUPERHEAT CHARGING TABLE ˚C

EVAPORATOR ENTEREING AIR ˚F AT WB

EVAPORATOR ENTEREING AIR ˚C AT WB

˚F

50 52 54 56 58 60 62 64 66 68 70 72 74 76

˚C

10 11 12 13 14 16 17 18 19 20 21 22 23 24

Outdoor

Temp

SUPERHEAT ˚F AT LOWSIDE SERVICE PORT

Outdoor

Temp

SUPERHEAT ˚C AT LOWSIDE SERVICE PORT

55

9 12 14 17 20 23 26 29 32 35 37 40 42 45

13

5 7 8 9 11 13 14 16 18 19 21 22 23 25

60

7 10 12 15 18 21 24 27 30 33 35 38 40 43

16

4 6 7 8 10 12 13 15 17 18 19 21 22 24

65

6 10 13 16 19 21 24 27 30 33 36 38 41

18

3 6 7 9 11 12 13 15 17 18 20 21 23

70

7 10 13 16 19 21 24 27 30 33 36 39

21

4 6 7 9 11 12 13 15 17 18 20 22

75

6 9 12 15 18 21 24 28 31 34 37

24

3 5 7 8 10 12 13 16 17 19 21

80

5 8 12 15 18 21 25 28 31 35

27

3 4 7 8 10 12 14 16 17 19

85

8 11 15 19 22 26 30 33

29

4 6 8 11 12 14 17 18

90

5 9 13 16 20 24 27 31

32

3 5 7 9 11 13 15 17

95

6 10 14 18 22 25 29

35

3 6 8 10 12 14 16

100

8 12 15 20 23 27

38

4 7 8 11 13 15

105

5 9 13 17 22 26

41

3 5 7 9 12 14

110

6 11 15 20 25

43

3 6 8 11 14

115

8 14 18 23

46

4 8 10 13

*Optimum performance point, 82°F (28°C) outdoor ambient and (80°F / 27°C dry bulb), (67°F / 19°C wet bulb) indoor conditions. (DOE B Test

Conditions)

Where a dash (-) appears do not attempt to charge system under these conditions or refrigerant slugging may occur. Charge must be

weighed in.

Note

: Superheat °F is at low-side service port, Allow a tolerance of ± 3°F (± 1.7°C)

Note

: Indoor dry bulb between 70°F and 80°F (21°C and 27°C)

Figure

14

SUCTION PRESSURE AT SERVICE PORT PSIG

SUCTION PRESSURE AT SERVICE PORT kPA

SUPER-

HEAT

TEMP

˚F

108

112

117

121

126

131

139

141

146

SUPER-

HEAT

TEMP

˚C

743

774

805

836

869

902

957

971 1005

REQUIRED SUCTION TUBE TEMPERATURE

˚F

(MEASURED AT LOW-SIDE SERVICE PORT)

REQUIRED SUCTION TUBE TEMPERATURE

˚C

(MEASURED AT LOW-SIDE SERVICE PORT)

0

35

37

39

41

43

45

47

49

51

0

2

3

4

5

6

7

8

9

11

2

37

39

41

43

45

47

49

51

53

1

3

4

5

6

7

8

9

11

12

4

39

41

43

45

47

49

51

53

55

2

4

5

6

7

8

9

11

12

13

6

41

43

45

47

49

51

53

55

57

3

5

6

7

8

9

11

12

13

14

8

43

45

47

49

51

53

55

57

59

4

6

7

8

9

11

12

13

14

15

10

45

47

49

51

53

55

57

59

61

6

7

8

9

11

12

13

14

15

16

12

47

49

51

53

55

57

59

61

63

7

8

9

11

12

13

14

15

16

17

14

49

51

53

55

57

59

61

63

65

8

9

11

12

13

14

15

16

17

18

16

51

53

55

57

59

61

63

65

67

9

11

12

13

14

15

16

17

18

19

18

53

55

57

59

61

63

65

67

69

10

12

13

14

15

16

17

18

19

21

20

55

57

59

61

63

65

67

69

71

11

13

14

15

16

17

18

19

21

22

22

57

59

61

63

65

67

69

71

73

12

14

15

16

17

18

19

21

22

23

24

59

61

63

65

67

69

71

73

75

13

15

16

17

18

19

21

22

23

24

26

61

63

65

67

69

71

73

75

77

14

16

17

18

19

21

22

23

24

25

28

63

65

67

69

71

73

75

77

79

16

17

18

19

21

22

23

24

25

26

30

65

67

69

71

73

75

77

79

81

17

18

19

21

22

23

24

25

26

27